Water Bottle Washing Line Instruction:

This water bottle washing line is mainly used for filling drinking water. Water washing line combines rinsing and filling and capping as one automatic body suitable for PET or other plastic bottles. The micro pressure filling operation of the new type is adopted enabling water washing line to fill more efficiently and more stably with more output than the machine of the same level from others. Water washing line is suitable for 350-1500ml PET bottles mineral water, drinking water, pure water etc.

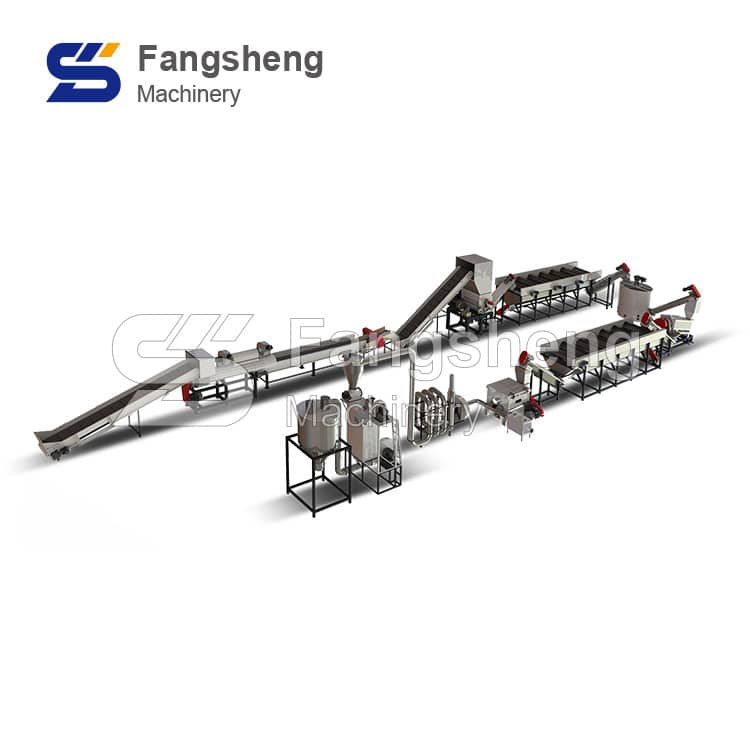

Water Washing Line Machinery:

1. (Making bottles) Automatic bottle blowing machine or Semi automatic bottle blowing machine.

2. (Water purification system) RO water purification machine / UF mineral water filtration machine.

3. (Filling water into the bottle) Bottle washing filling and capping machine.

4. (Printing the date on the bottled water) CO2 laser date printing machine.

5. (Labeling bottled water) Shrink sleeve labeling machine or Sticker labeling machine.

6. (Package the bottled water) Automatic PE film shrink wrapping packing machine or Semi automatic PE film shrink wrapping packing machine / Carton box packing machine.

Water Bottle Washing Line Video:

Water Washing Line Detail:

Water Washing Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |