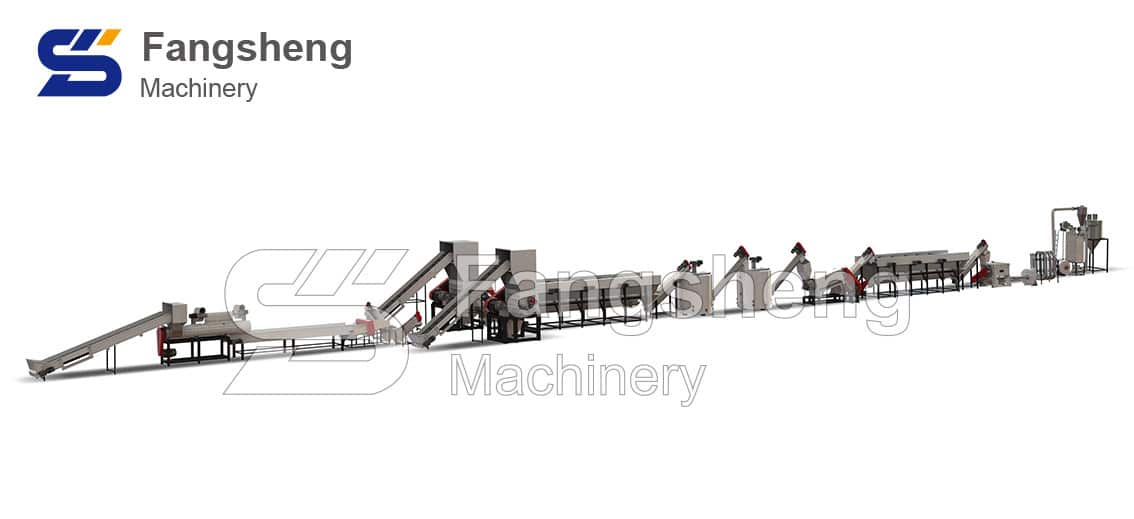

Water Bottle Recycling Washing Machine Instruction:

Water bottle recycling washing machine is mainly used to recycle used PET bottles, water bottles, cola bottles, PET flakes and PET packaging containers. The recycled waste Coke bottle PET recycling machine can easily remove labels, caps, rings, glue, dirt and other impurities and finally you will get the ideal PET flakes. All your requirements for recycled waste Coke bottles PET recycling machine will be fulfilled.

Water bottle washing machine is mainly used for washing and cleaning of PET materials. pvc and some other plastics can also be cleaned by this line. The whole line is fully automatic and the machine has high efficiency, low noise and easy operation.

Water bottle washing machine adopts hot water for washing to get good quality. There are many kinds of output available: 300KG/H, 500KG/H, 1000KG/H, 1500KG/H, 2000KG/H and 3000KG/H. If you need more output, then the machine needs to be customized according to your requirements.

The recycling line can easily crush, clean and granulate waste plastic products from start to finish. Waste agricultural films and waste packaging materials or rigid plastics can be processed step by step by this machine.

Water Bottle Washing Machine Video:

Water Bottle Washing Machine Detail:

Water Bottle Washing Machine Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

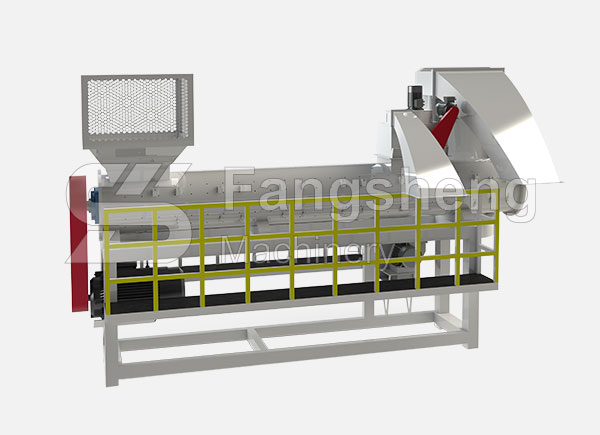

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

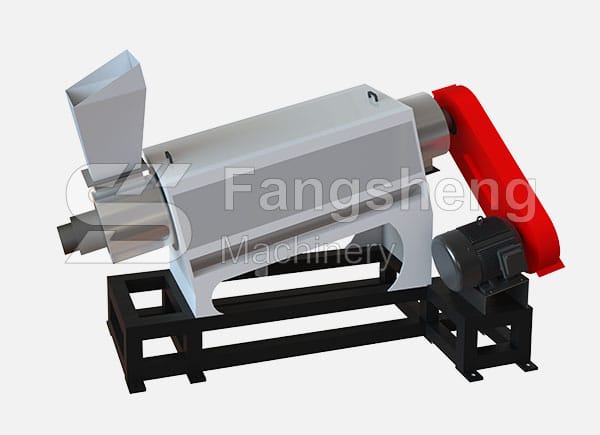

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |