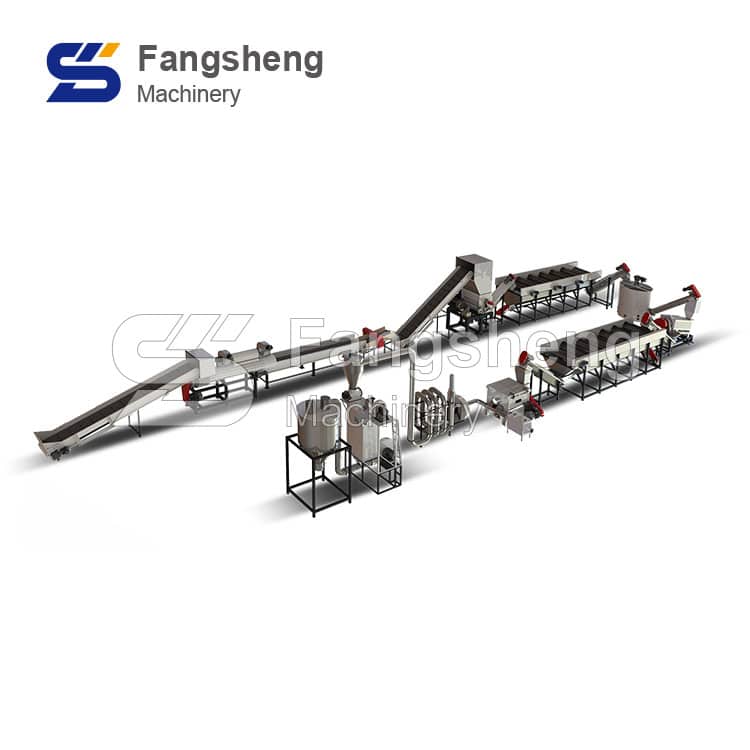

Water Bottle Recycling Line Features:

1. High automation level to minimize your labor cost (especially for three shifts) and ensure high processing capacity: 500-6000/hr.

2. Friendly control system (PLC integration and individual control of each machine) and touch screen panel for easy operation, monitoring and emergency stop.

3. All parts in contact with plastic material and water are made of high quality 304 stainless steel to ensure no secondary contamination of flakes.

4. This bottle recycling line can easily clean and recycle used PET bottle flakes. The equipment at the end of the cleaning line can collect and package the completely dry flakes directly after cleaning.

5. The whole water bottle recycling line can be designed according to the degree of soiling of flakes to ensure the quality of the final product.

Water Bottle Recycling Line Description:

The material from the water bottle recycling line is fed to the crusher for coarse crushing through the feed conveyor, then sent to the crusher on the conveyor for fine crushing, and finally the crushed material is separated from the material and dust through the collection and suction device to make the material more pure.

Bottle Recycling Line Process Flow Introduction:

Bottle pack → unpacking → roller filtering → de-labeling → bottle pre-washing → bottle selection sorting → manual sorting → wet crushing → flotation washing → drying → hot flotation machine → drying → continuous friction → continuous flotation washing → drying → fluidized bed drying → mixing → labeling & dust remover → metal separation → flake optical sorting → packaging

Clean Flake → Clean Flake

Bottle Recycling Line Video:

Bottle Recycling Line Detail:

Bottle Recycling Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |