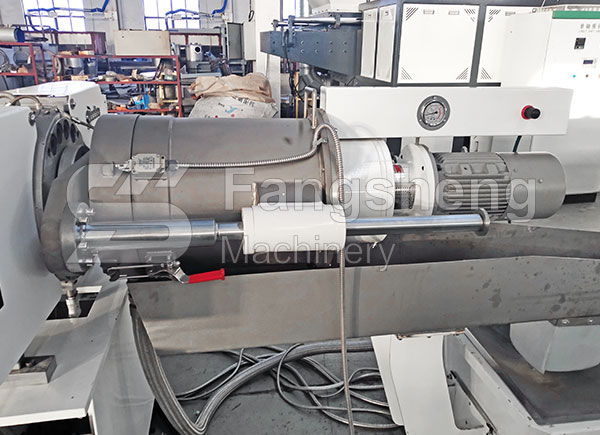

Waste Film Granulation Production Line Description:

The granulation method of waste film granulation production line adopts water ring granulation, and the granules are in the shape of round tablets. Compared with the traditional stretch granulation method, the granules cut out by water ring granulation are uniform in size without changing the screen. The problem, the equipment occupies less space and other advantages.

The waste film granulator is equipped with a cutter head and a fixed knife on the inner wall to cut the broken film, and generates heat under high-speed cutting friction to cause the material to shrink by heat, increase the bulk density and increase the feed rate. The material after heat shrinkage is loaded through the inner wall. The set deflector is thrown into the screw of the main engine.

Waste Film Granulation Line Process Flow:

1. Dense storage→2. Single screw main engine→3. Screen changer→4. Water ring pelletizing→5. Dehydration. According to your requirements, you can choose single-stage film granulator or two-stage film granulator.

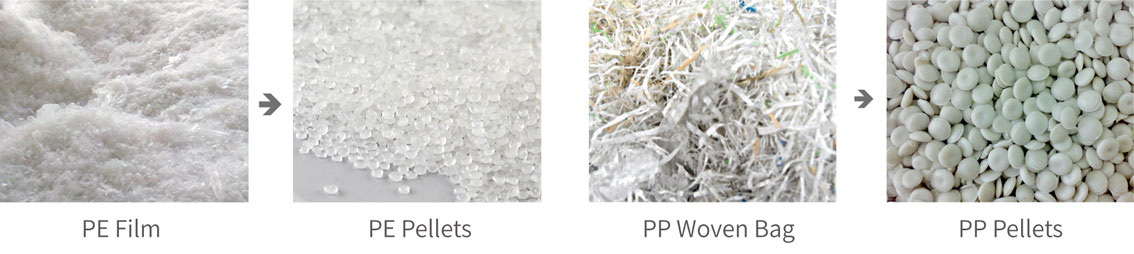

Waste Film Granulation Line Application:

Waste Film Granulation Line Video:

Learn more about YouTube’s waste film granulation line

Waste Film Granulation Line Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |

Waste Film Granulation Line Detail: