Waste engine oil bottle recycling washing line is researched, design and manufactured by Fangsheng Machinery, integration of Europe technology. The engine oil bottle recycling washing machine has features as high efficiency, working stable, large capacity etc.

Fangsheng Machinery is a professional manufacturer and supplier of waste engine oil bottle washing line. High quality, stable performance.

Engine Oil Bottle Recycling Washing Line Advantages:

1.Final products has good quality. When process engine oil bottle, final products humidity below 1%, impurities less 150ppm

2.Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service lift time

3.World famous brand components applied on the engine oil bottle washing line- NSK bearing, Siemens contactor, Omron temperature, FUJI invertor, Siemens PLC controletc.

4.The engine oil bottle washing line with CE certification, ISO9001 certification.

Engine Oil Bottle Washing Line Video:

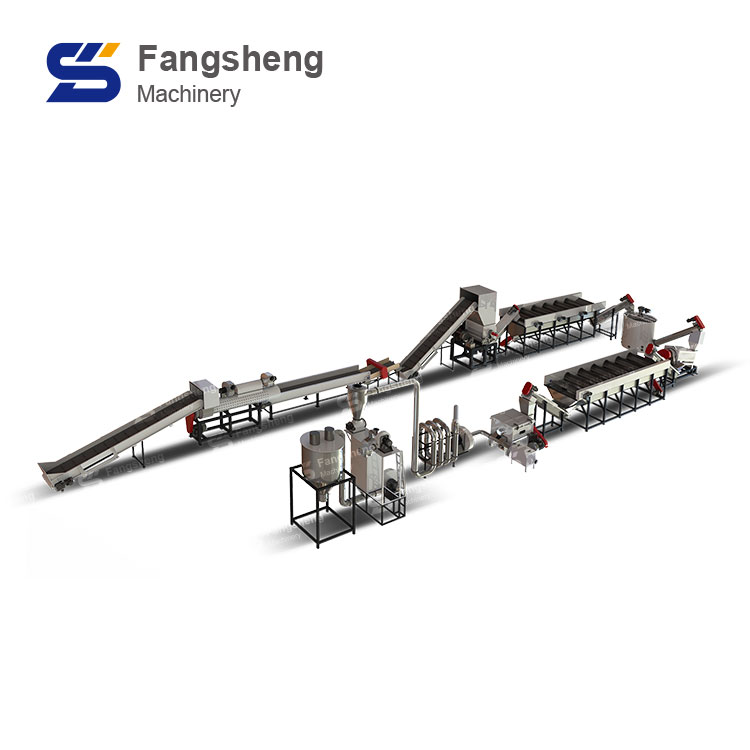

Engine Oil Bottle Washing Line Flow Chart:

Belt conveyer → Wet crusher → Screw conveyer → Floating washer → Screw conveyer → High speed friction washer → Screw conveyer → Dewatering machine → Drying system1 → Silo for transition → Drying system2 → Storage hopper

Engine Oil Bottle Recycling Line Application:

Waste Engine Oil Bottle Recycling Line Detail:

Engine Oil Bottle Washing Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |