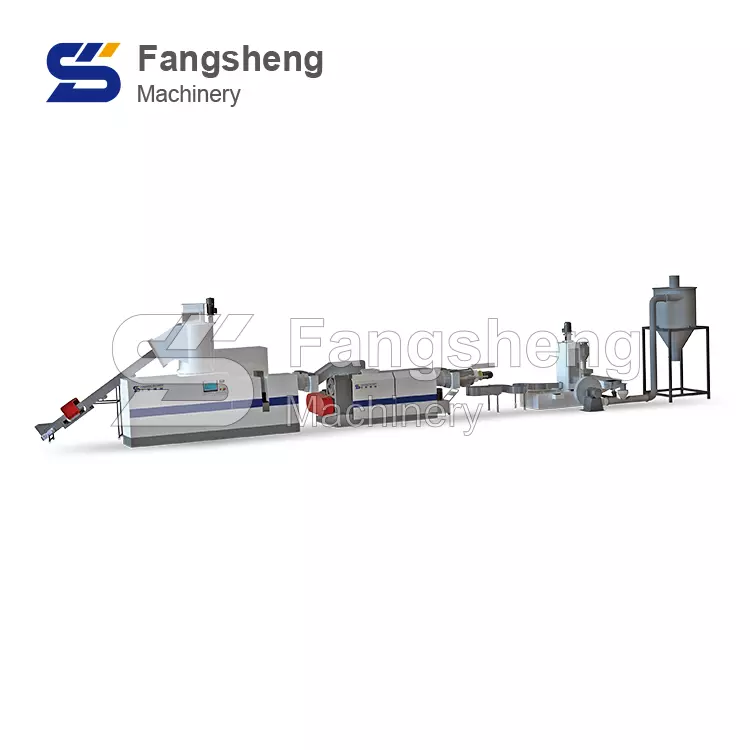

The two stage plastic recycling pelletizing machine is a type of equipment used in the manufacturing of plastic pellets. This pelletizing machine is designed to melt and process plastic materials into pellets in two stages.

In the first stage, the plastic material is melted and extruded through a die to form strands or spaghetti-like strings. These strands are then cooled and solidified by passing them through a water bath or air cooling system.

In the second stage, the cooled strands are fed into a pelletizer machine, where they are cut into small, uniform-sized pellets. The pelletizer uses a rotating cutting blade to chop the strands into pellets of the desired length.

The advantage of a two stage pelletizing machine is that it can produce pellets of higher quality and consistency compared to a single stage machine. This is because the two-stage process allows for better control over the cooling and solidification of the plastic, which can affect the final pellet properties.

Two stage pelletizers are commonly used in the production of a wide range of plastic products, including film, woven bag and more. They can process various types of plastic materials, including polyethylene, polypropylene, polystyrene, ABS,PET and PVC, among others.

Two Stage Pelletizing Machine Video:

Technical Parameter:

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |