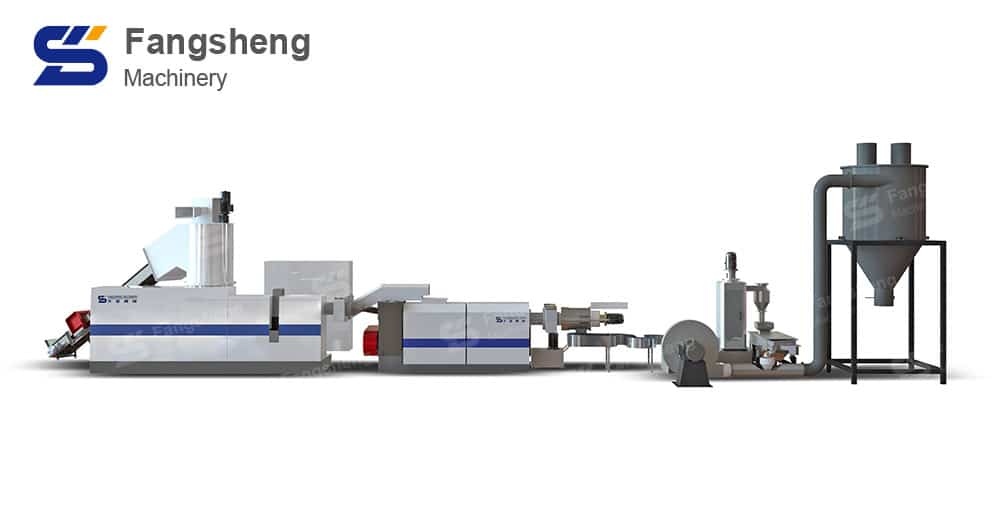

PP Woven Bag Pelletizing Production Line Description:

PP woven bag pelletizing production line is suitable for the regeneration and pelletizing of waste woven bags. The output is 100-1000kg/h.

Woven bag pelletizing production line is mainly composed of: conveyor belt, compaction bin, single screw extruder, hydraulic die head screen changing device, cooling water tank, pelletizer, air feeding bin, control electric box, etc.

PP Woven Bag Pelletizing Production Line Features:

1. The woven bag pelletizing line has a high degree of automation and is a fully automatic assembly line. As long as someone adds waste plastic in the front and someone in the back picks up the finished pellets, it is enough to realize the direct transformation from waste plastics to finished pellets.

2. The woven bag pelletizing line is continuously improved on the basis of the German equipment drawings. The design is reasonable, the appearance is beautiful, and it is durable. The parts in contact with the materials are made of stainless steel.

3. The produced particles are of high quality, without bubbles, and are full and round.

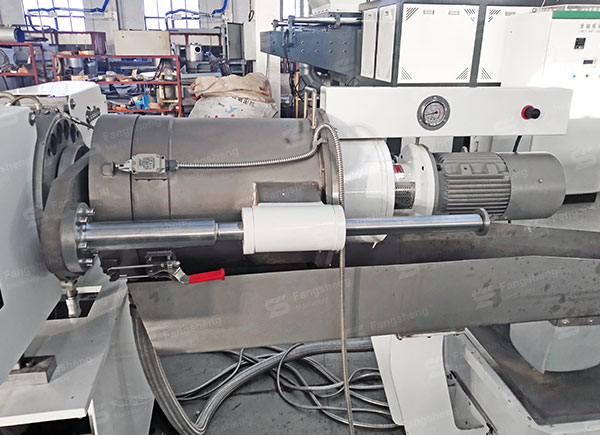

4. The screw and barrel of the pelletizing line are made of 38CrMoAl, and the surface is nitrided and hardened, which has a long service life.

5. The gearbox of the pelletizing line adopts the hard-tooth surface oil-cooled gearbox, which is half the weight of the soft-tooth gearbox, is resistant to wear, and the service life is increased by 3 to 4 times, and the carrying capacity is increased by 8 to 10 times.

6. The woven bag pelletizing line cuts pellets directly after cooling, and then is sent to the storage bin by the fan, so there will be no problem of broken filaments.

7. There is a drainage port and a vacuum pump on the barrel of the woven bag pelletizing line to drain and exhaust to ensure the quality of the particles.

PP Woven Bag Pelletizing Line Application:

PP Woven Bag Pelletizing Line Video:

PP Woven Bag Pelletizing Line Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |

PP Woven Bag Pelletizing Line Detail: