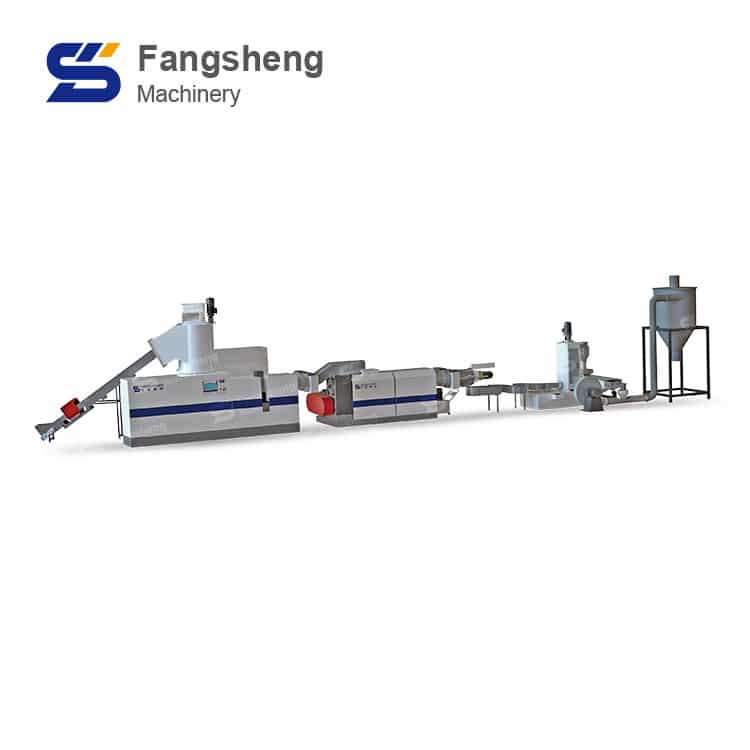

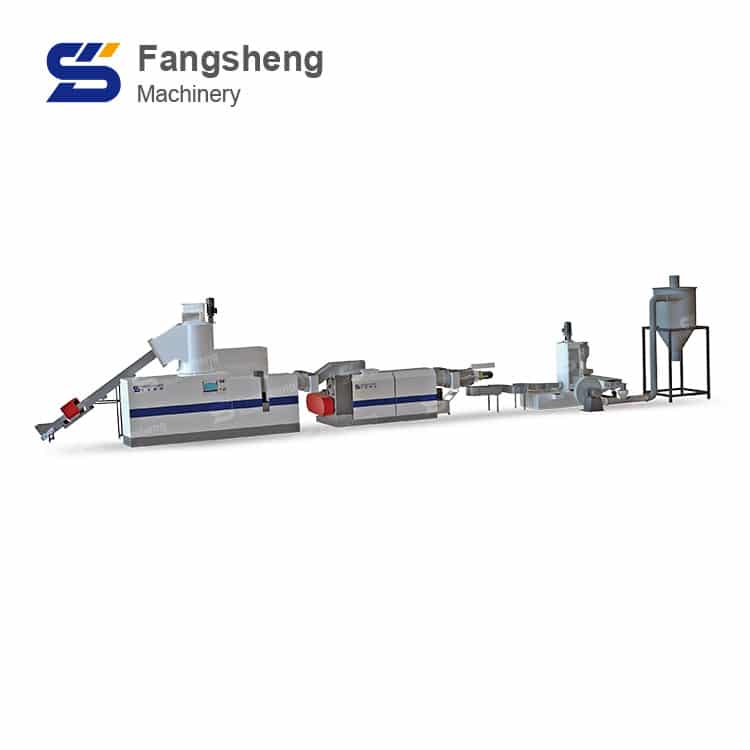

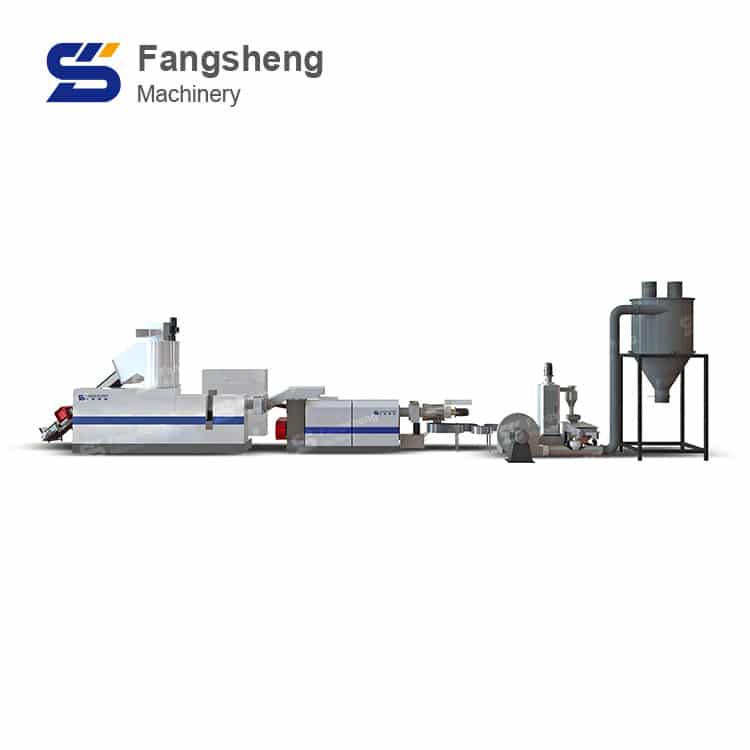

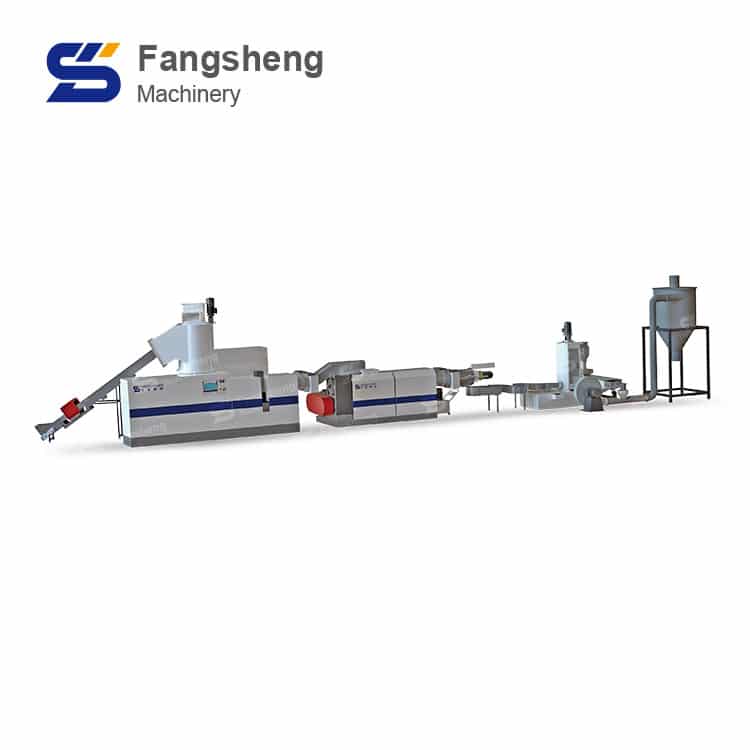

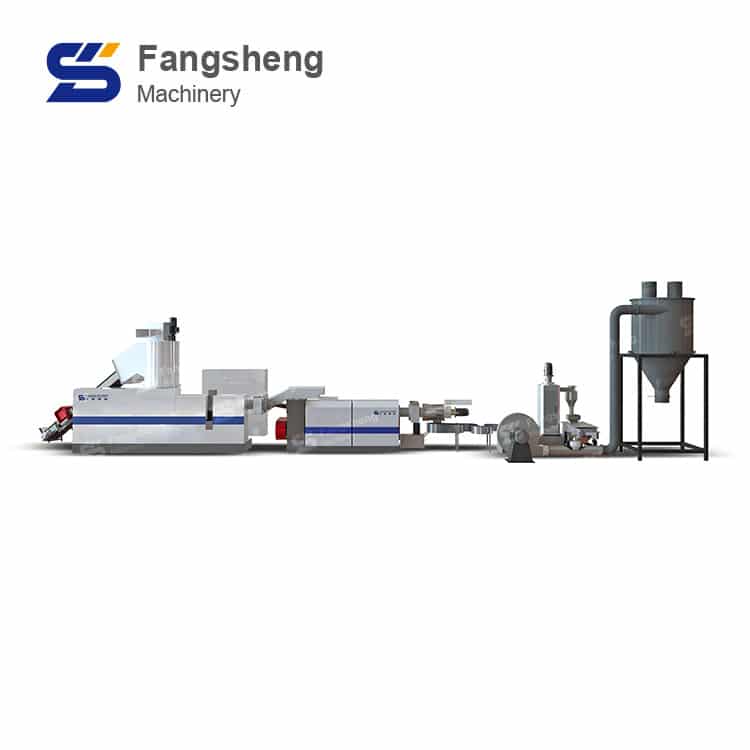

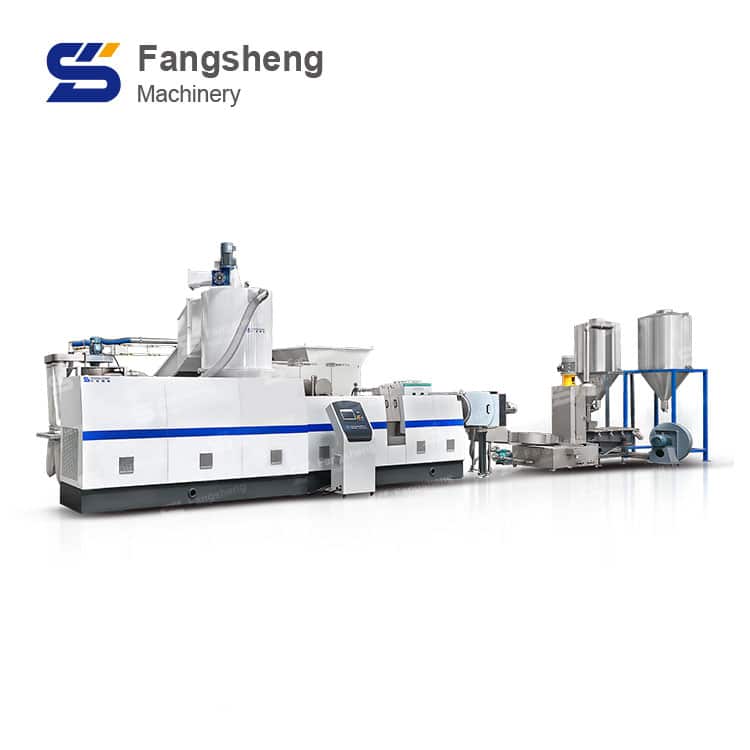

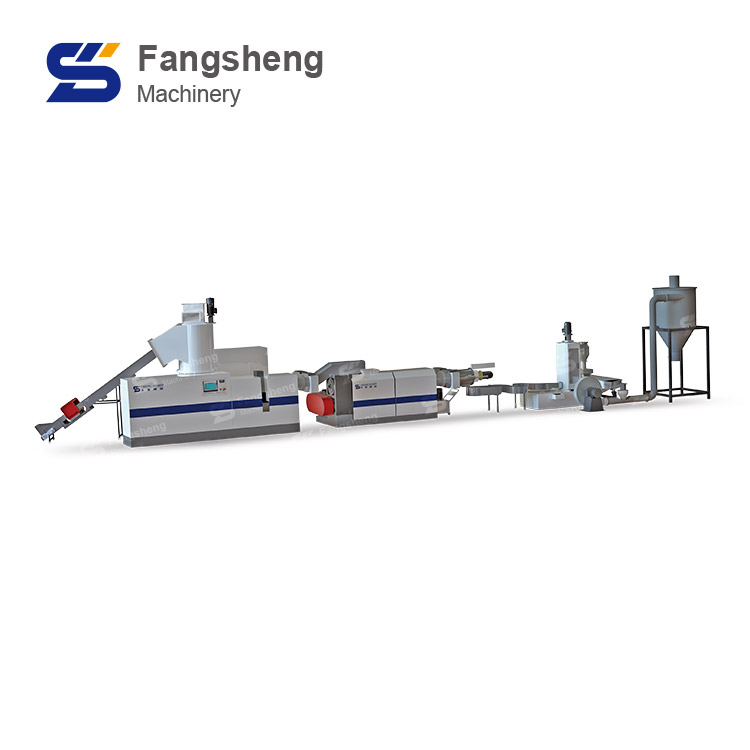

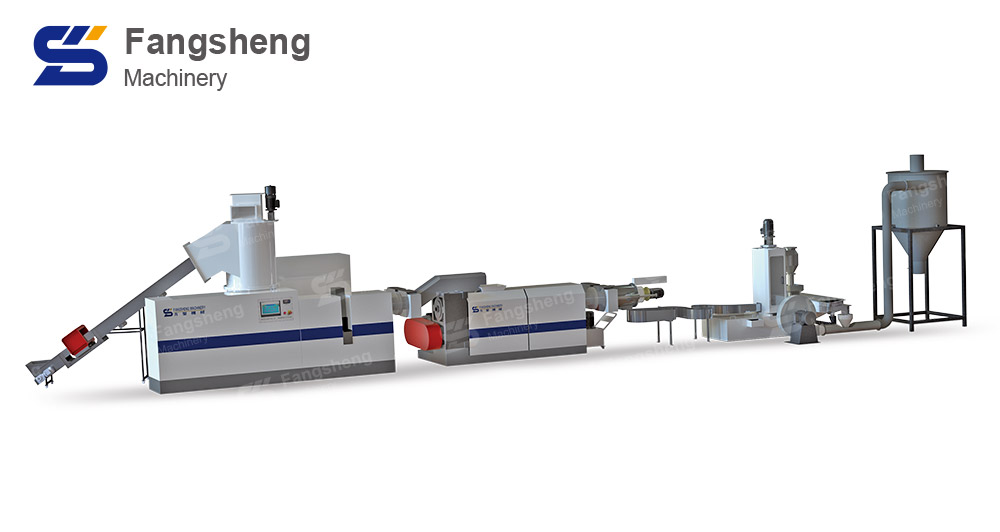

PP woven bag pelletizing line is special equipment for the PP woven bag / raffia bag / jumbo bag bagrecycling granulating, equipped with comacting machine which cound pre- compact the woven bag into smaller granules.

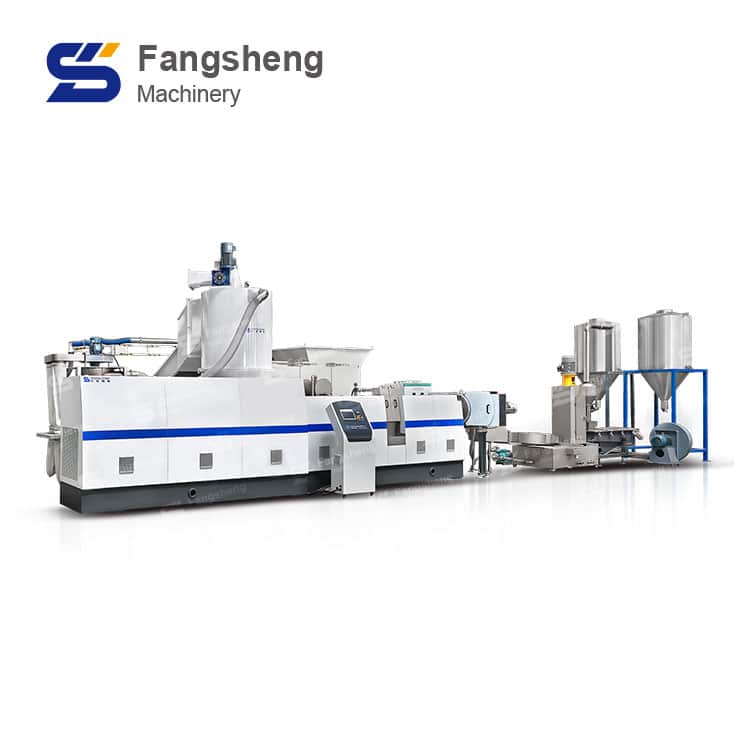

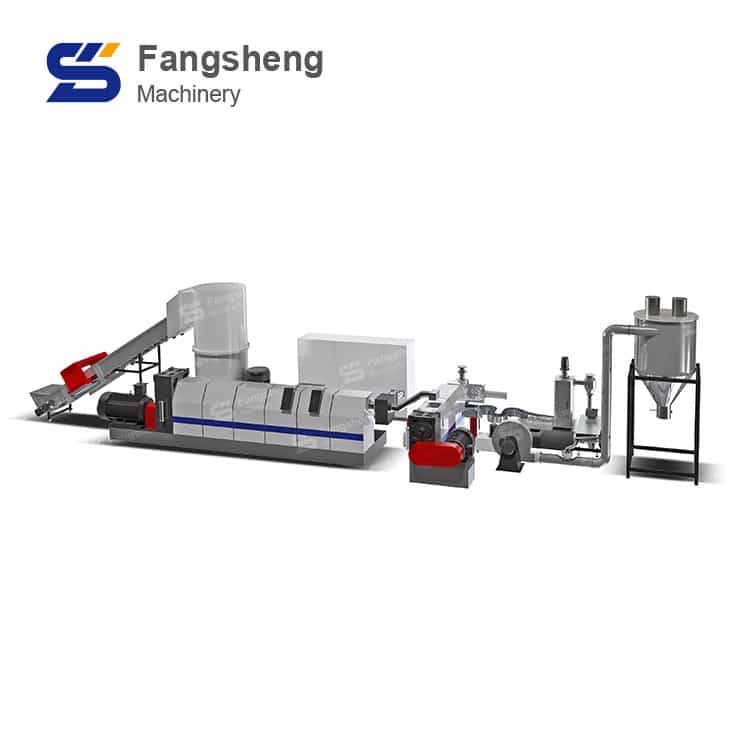

PP woven bag pelletizing line is special equipment for the PP woven bag / raffia bag / jumbo bag bagrecycling granulating, equipped with comacting machine which cound pre- compact the woven bag into smaller granules, then easily feed into screw barrel of extruder, its efficiency is high and can improve production capacity and save labour cost.

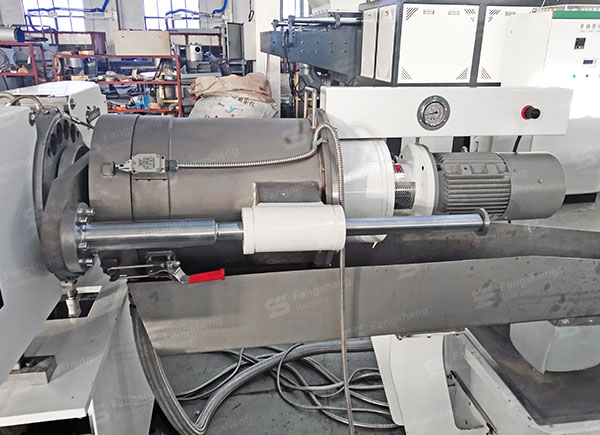

At the end of screw barrel, equipped with double post fast speed hydraulic non -stop screen changer which can effetively filt out the dirty in the plastic melt.

The woven bag pelletizing machine adopts water flush pelletizing which is easier to operate, and the shape and appearance of granule is good.

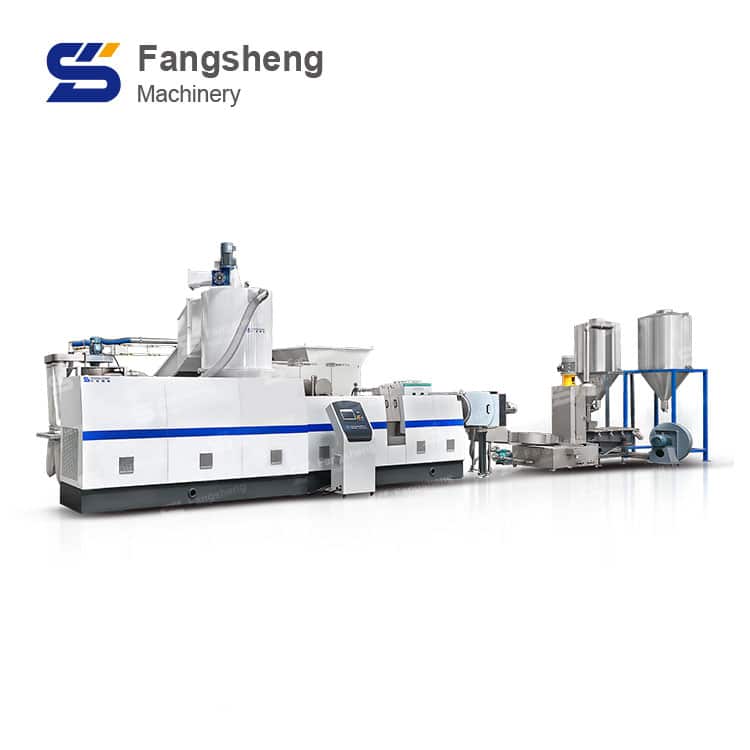

1. Highly efficent: the woven bag pelletizing line is automatic and with less power consumption.

2. Special screw design: Fangsheng Machinery will design the screw up to customer different material and the material of screw and barrel can be 38CrMoAL or bimetallic.

3. Material come out more stably: material go through from the first stage to the second stage, with two screen changer, much more impurity will be filterd and the material come out from the die won’t broken down.

4. Beautiful pellets: two degassing system, no air in the pellets.

5. The woven bag pelletizing machine wih long life.

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |