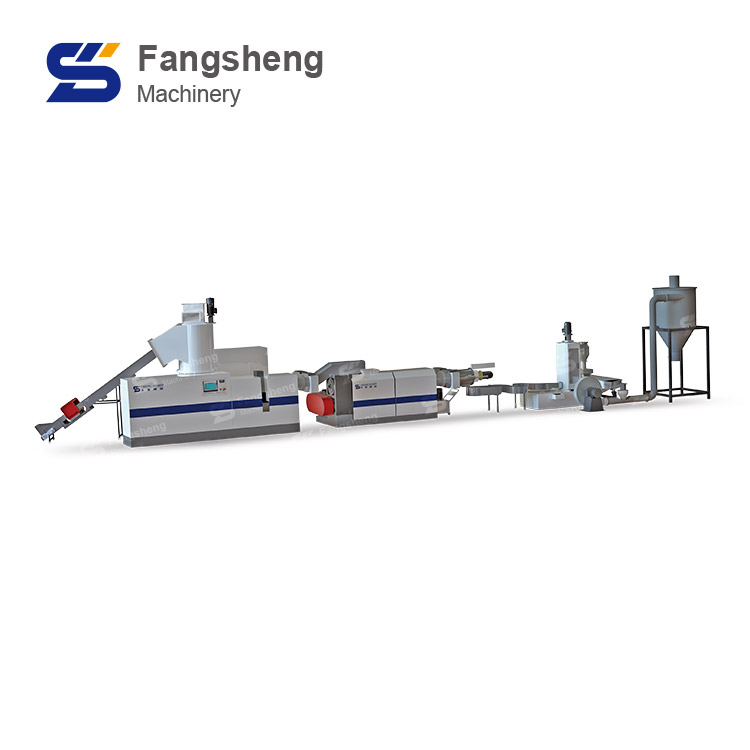

PP Raffia Bag Pelletizing Line Description:

PP raffia bag pelletizing line has a high degree of automation, only needs to manually add the woven bag before the feeding machine, and finally the finished particles are bagged and packaged, realizing the direct transformation from waste plastics to finished pellets. The process flow of the PP raffia bag pelletizing machine is simple to operate, practical, high in output and long in service life. The production capacity of the PP raffia bag pelletizing production line under the standard configuration can meet the needs of users of 60-80 tons/month.

PP raffia bag pelletizing machine has been continuously improved and upgraded to meet the needs of most film granulation users, with durable machinery and stable performance. The produced particles are beautiful in appearance, the shape is in the form of a disc, and the size and thickness can be adjusted; the particles are of high quality, without bubbles, and are full and round.

There is a drainage port and a vacuum pump on the barrel of the PP raffia bag pelletizing machine to drain and exhaust to ensure the quality of the particles.

PP Raffia Bag Pelletizing Line Application:

PP Raffia Bag Pelletizing Machine Video:

PP Raffia Bag Pelletizing Machine Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |