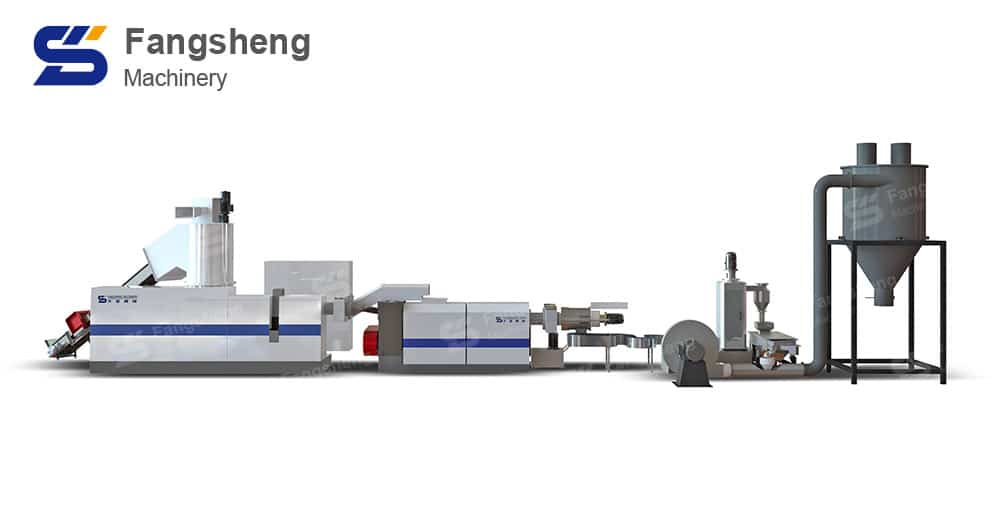

PP Jumbo Bag Pelletizing Line Description:

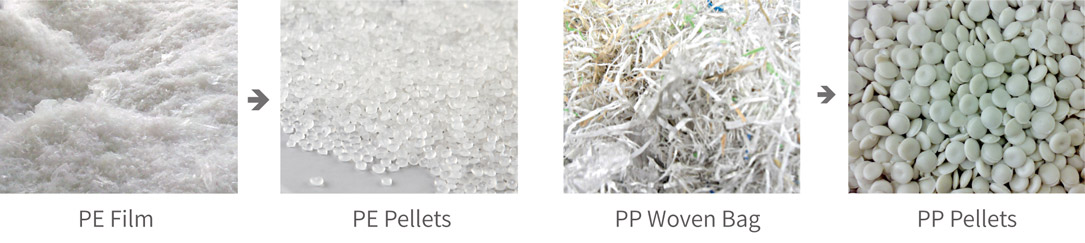

PP jumbo bag pelletizing line is mainly used for recycling and granulating waste plastics. Recycled plastics of different shapes and different compositions are granulated to obtain plastic particles of the same size. PP jumbo bag pelletizing machine can adopt corresponding special screw design and different configurations according to the different needs of users. The jumbo bag pelletizing machine adopts a high-torque, hard-tooth surface reducer to ensure stable operation and no noise. The special hardened surface treatment of the screw and barrel has good mixing performance and wear resistance.

The granulation method of the jumbo bag pelletizing line is that the plastic is extruded in the melt state, scraped by the blade, and solidified by circulating cold cutting water. After being dehydrated by a high-speed dehydrator, the water in the finished granules can be effectively removed. The drying effect is good, the pelletizing process is easy to operate, the degree of automation is high, there is no dust, the noise is low, the quality of the slicing is good, and the appearance is beautiful.

PP Jumbo Bag Pelletizing Machine Application:

PP Jumbo Bag Pelletizing Machine Video:

PP Jumbo Bag Pelletizing Machine Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |

PP Jumbo Bag Pelletizing Machine Detail: