PP Jumbo Bag Granulating Production Line Description:

PP jumbo bag granulating production line is composed of screw feeder, special design compactor cutter, single screw extruders, hydraulic screen changer, die-head, dewatering machine/fan dryer, vibration screen(optional), storage silo and packing&weighting system(optional). PP jumbo bag granulating line has highly automatic, user-friendly control, high efficient, environmental protection and energy saving.

Fangsheng Machinery provides a variety of specifications according to customer requirements, such as different length-to-diameter ratios, multi-exhaust screw structures, single and double-stage extruders, and different types of pelletizers.

PP Jumbo Bag Granulating Production Line Features:

1. High efficient compactor cutter ensures high capacity feeding, low energy consumption, steady operation, low noise.

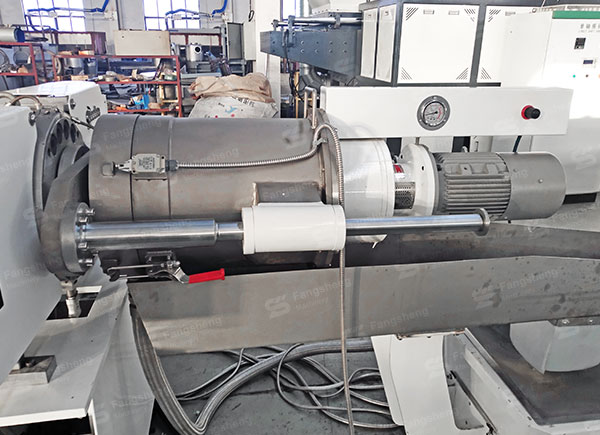

2. Single screw extruder, equipped with specially designed screw&barrel, venting system, high production output.

3. PP jumbo bag granulating line style: water-ring cutting with extrusion mould, noodle cutting ensures good shape.

4. Auxiliary machine: pellets cooling&classifying, packing&weighing.

PP Jumbo Bag Granulating Line Application:

PP Jumbo Bag Granulating Line Video:

PP Jumbo Bag Granulating Line Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |

PP Jumbo Bag Granulating Line Detail: