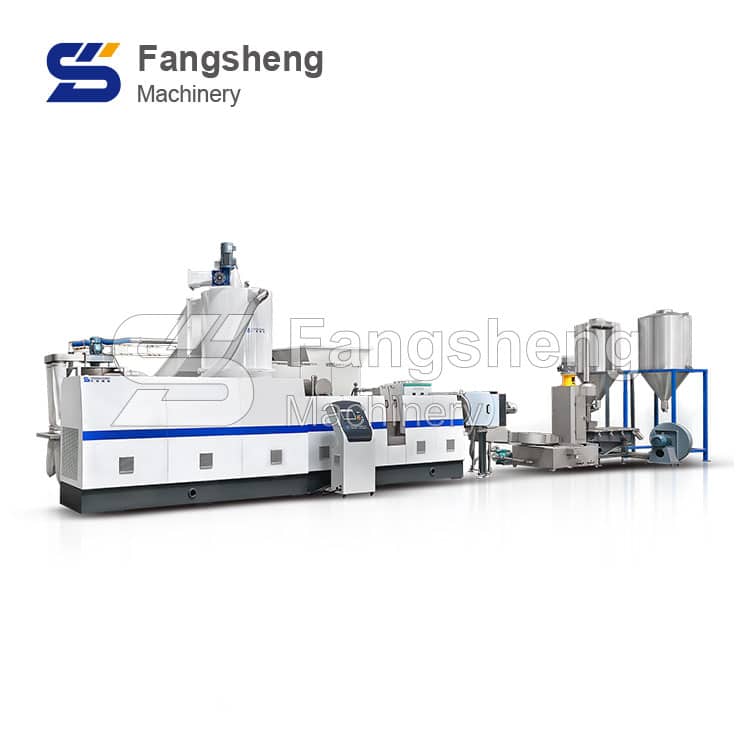

Plastic Pellet Making Machine Description:

Plastic pellet making machine is widely used in granulation of PE, HDPE, LDPE plastic films after washing. Plastic pellet making machine adopts forced feeding hopper is adapted for uniform feeding, labor saving, and high output. Screw of the plastic pellet making line is designed in accordance with the characteristics of the raw material. The pellet making machine is of high output, and the finished products are of good luster and are of full and plump appearance. With the configuration enhanced, the service life of the pellet making machine is profoundly prolonged.

Plastic pellet making line has the characteristics of high yield of low energy consumption, large torque reducer and motor. With a specially designed screw with, no dead angle and no material congestion are ensured, the production capacity is effectively improved, and the plastic plasticizing effect is increased. Single and double exhaust structures are all available. Dry, wet materials, materials can be fully drained and exhausted to ensure the ideal pelletizing effect of producing firm and full particles.

Plastic Pellet Making Machine Application:

Plastic Pellet Making Line Video:

Learn more about YouTube’s plastic pellet making line

Plastic Pellet Making Line Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |