Plastic granulating line is a machine that makes cleaned waste plastic into plastic granules. Enterprises often produce excess plastic scraps during the production process.

These plastics can be directly fed into the granulator for granulation, and the produced granules can be processed into the required plastic products.

Plastic granulating line has functions such as crushing, heating, extrusion, granulation, dehydration, etc. Depending on the raw materials, it can also be equipped with a crusher and a shredder, so that the raw materials can be heated and melted more easily.

1.The raw materials are conveyed into the chamber through a belt and chopped and heated by the blades inside.

2.The melted raw materials enter the extruder for extrusion and granulation, and the granules are cooled by a water ring

3.The cooled granules are dehydrated by the dehydrator and then enter the vibrating screen, where they are screened to obtain particles that meet the requirements.

Plastic granulator is suitable for a variety of plastics, such as PE PP PET HDPE LDPE POF BOPP ABS PA, etc.

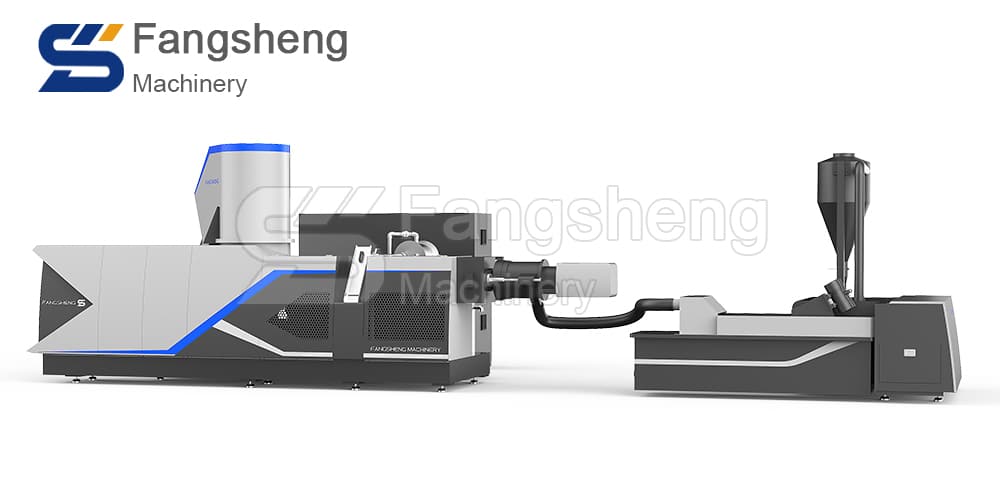

Customers can choose single-stage or double-stage granulation.

The double-stage granulation has one more extruder than the single-stage one, which has higher output and the extruded particles are better and cleaner

Output: 100-1000kg/h

Plastic granulator can help enterprises reduce raw material costs and improve production efficiency.

Follow us