Plastic Film Recycling Pelletizing Line Description:

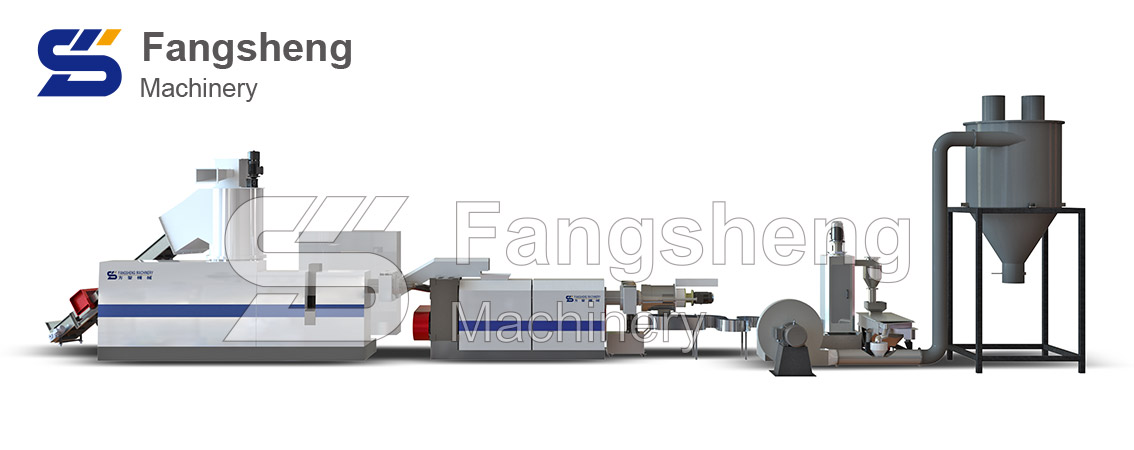

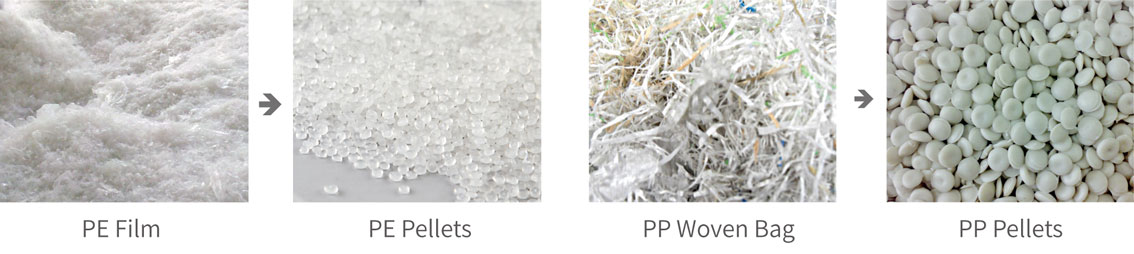

Plastic film recycling pelletizing line is specially designed by Fangsheng Machinery, which is mainly used for processing waste plastic film (industrial packaging film, agricultural film, packaging bags, etc.), woven bags, etc.

The plastic film is transported to the compactor through a belt conveyor. Then the material is cut, and then forced into the extruder, pelletizer, water tank, dehydrator, and finally blown into the storage hopper. According to your requirements, you can choose single-stage film pelletizer or two-stage film pelletizer.

Plastic Film Recycling Pelletizing Line Features:

1. The production capacity of the plastic film pelletizing line is between 100-1000 kg/h.

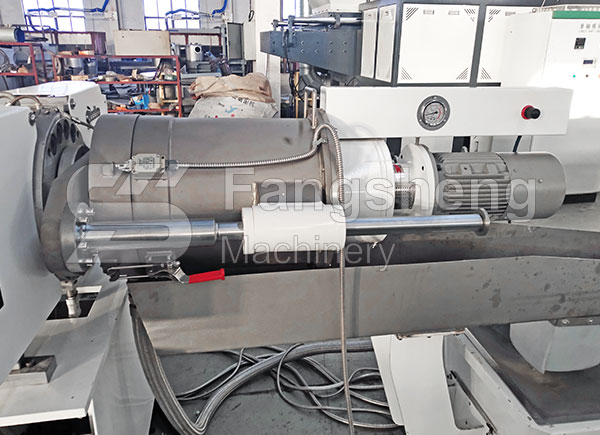

2. The parts in contact with the material are made of SUS304 with a thickness of more than 3 mm to ensure a long service life.

3. World-renowned brand components used in the plastic film pelletizing line-SKF bearings, Siemens contactors, ABB frequency converters, Siemens PLC control.

4. The plastic film pelletizer has CE certification and ISO9001 certification.

Plastic Film Pelletizing Line Application:

Plastic Film Pelletizing Line Video:

Learn more about YouTube’s plastic film pelletizing line

Plastic Film Pelletizing Line Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |

Plastic Film Pelletizing Line Detail: