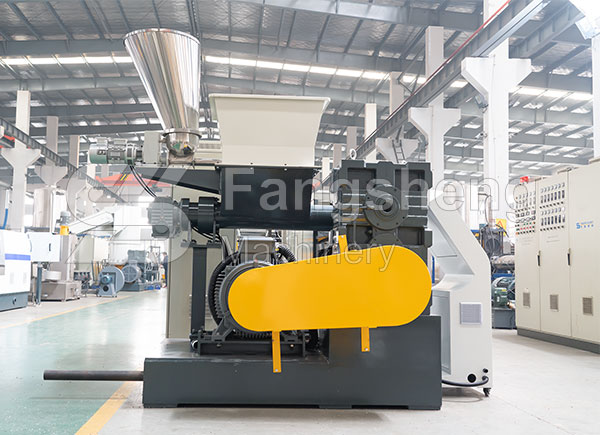

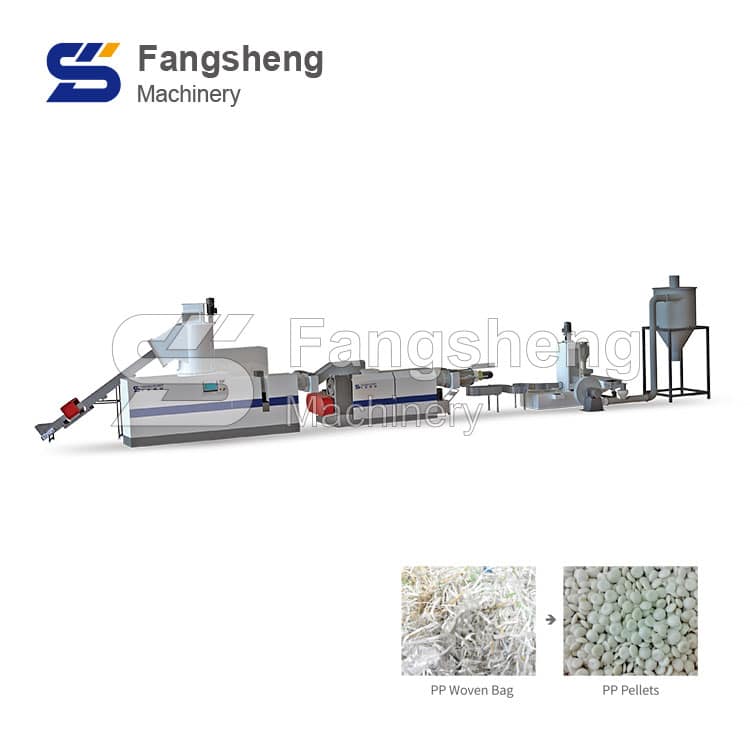

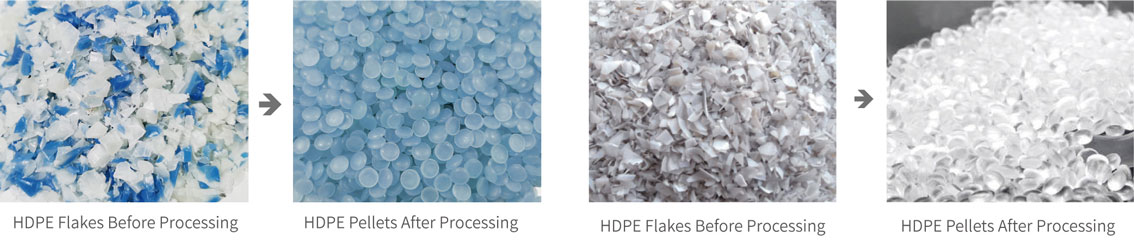

Plastic film / hard flakes pelletizing line is designed specially by Fangsheng Machinery, which is mainly used for processing of waste plastic film (industrial packaging film, agricultural film, greenhouse film, beer package, bag, etc.), hard flakes, etc.

Plastic film / hard flakes pelletizing line is designed specially by Fangsheng Machinery, which is mainly used for processing of waste plastic film (industrial packaging film, agricultural film, greenhouse film, beer package, bag, etc.), hard flakes, etc.

Through belt conveyer convey the PP/PE Film to compactor. Then the material will be cutted, then forced into extruder, cutting, water flume,dewatering machine, lastly blowing into storage hopper. Based on your requirements, you can choose compactor single stage granulator or double stage granulator.

1. The plastic pelletizing machine capacity between 200kg/h-1000kg/h.

2. Parts which contact material use SUS304, thickness more than 3mm, ensure long service life time.

3. World famous brand components applied on the pelletizing line- SKF bearing, Siemens contactor, Japan RKC temperature, ABB invertor, Siemens PLC control.

4. The plastic pelletizing machine with CE certification, ISO9001 certification.

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |