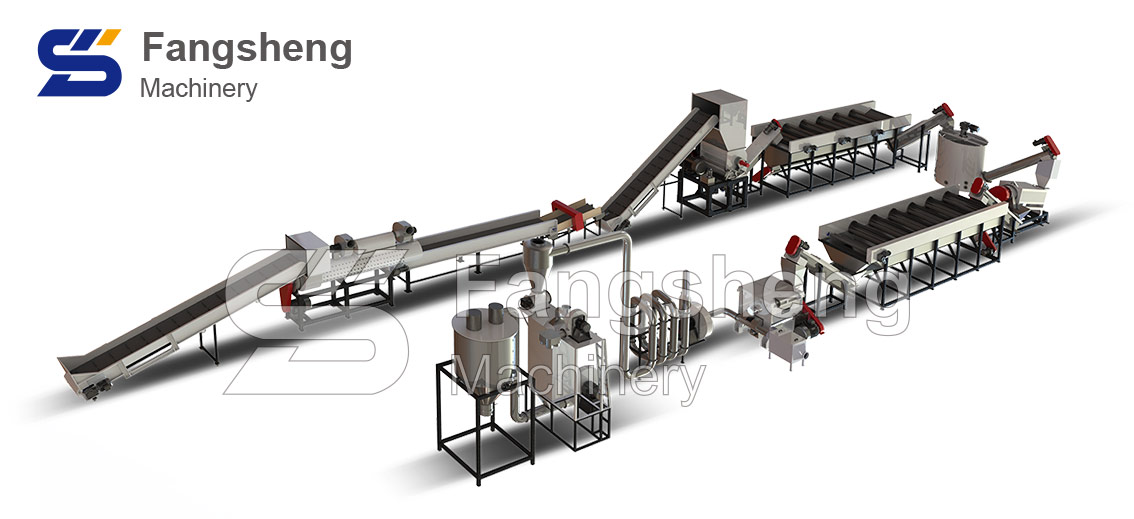

Plastic Bottle Washing Line Instruction:

Plastic bottle washing line is used for crushing, washing and drying of recycled waste plastic bottles and cans. This plastic bottle washing line is mainly used for PP PE bottles and cans, such as milk bottles, shampoo bottles, detergent bottles, oil cans, etc.

By the washing recycling, the final products are clean flakes with specified dimensions that can be reused for extrusion, injection molding and blow molding directly or after granulation.

Typically, a plastic bottle washing line includes heavy duty crushers, friction washers, rinse washers, centrifugal dewaterers, electric heaters, cyclone silos and control cabinets, as well as connecting units such as belt conveyors and screw feeders.

Stainless steel and carbon steel are used for different units by the different function.

By being equipped with single-shaft shredders and twin-shaft shredders, the plastic bottle washing and recycling line can also be used to recycle other large-sized plastic waste, such as plastic blue drums, car bumpers, pallets, crates, baskets, etc.

Bottle Washing Line Advantages:

1, High working efficiency.

2, Less energy consumption.

3, High degree of automation, saving labor.

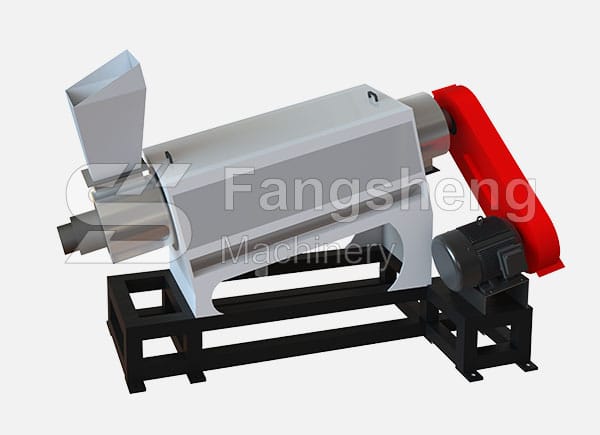

4, Heavy duty crusher has SKD-II blades with special installation angle for efficient cutting and long service life. With water spray design, the bottle washing line has good pre-washing and rotor cooling function.

5, Rinsing tank, screw feeder, pipes and bins are made of stainless steel, anti-corrosion and long service life.

6, The motor and electrical components are made of SIMO and SIEMENS and other famous brands, with smooth operation.

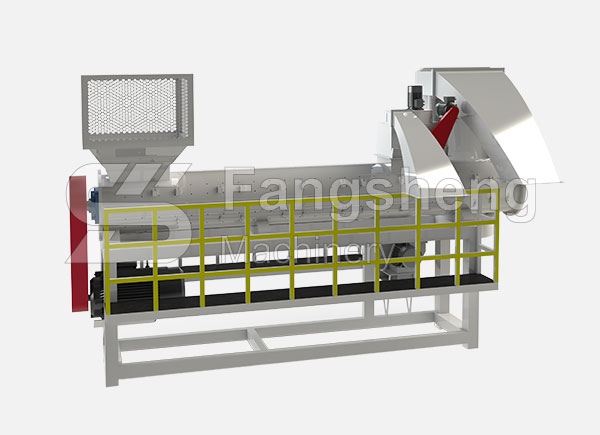

7, Through multiple friction cleaning and rinsing, the dirt can be fully washed.

8, Adopting high-speed centrifugal dewatering machine, with high dewatering rate.

9, The machine has solid structure, good balance performance, stable work and long service life.

10, The flow chart is reasonably designed, easy to operate and low maintenance cost.

Bottle Washing Line Video:

Bottle Washing Line Detail:

Bottle Washing Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |