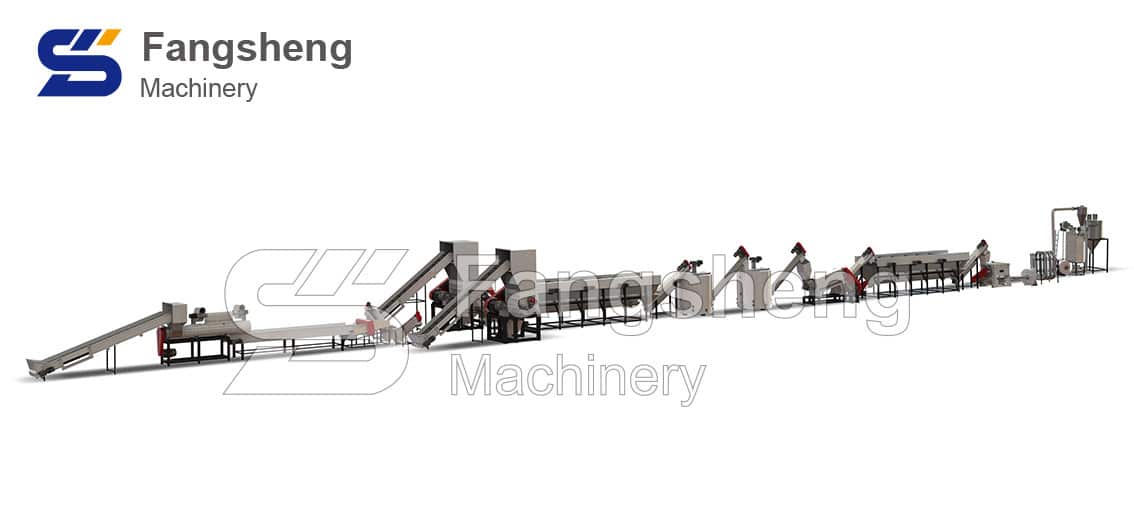

Plastic Bottle Recycling Washing Equipment Description:

This plastic bottle recycling washing equipment is mainly used to recycle waste PET bottles, water bottles, cola bottles, PET flakes and PET packaging containers. The waste Coke bottle PET recycling machine can easily remove labels, caps, rings, glues, dirt and other impurities, and finally you will get the ideal PET flakes.

1. This mineral water bottle recycling is mainly used to process waste PET bottles, barrels, etc.

2. The machine separates PET bottles from labels, caps, oil and garbage into flakes.

3. This plastic bottle washing machine is composed of separator, crusher, hot and cold washing system, dewatering, drying, packing system, etc.

4. Easy to operate and fully automatic.

Plastic Bottle Washing Equipment Instruction:

The whole plactic bottle washing production equipment has features as high efficiency, working stable, large capacity etc. Waste Plastic Pet Bottle Crushing Washing Drying Recycling Line / Machine / Plant is widely used to treat waste plastic, such as PET/PVC/HDPE bottle, water bottles, cola bottle and PET plastic scrap broken into flakes. Pet bottle recycling line is a crushing,washing, drying line. PET flakes are mainly used for the fiber production PET strap, PET sheet, and other related PET products.

With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad. this line can be displayed “L” or “U” shape .

1. Realize one production line can process different kinds of raw material.

2. Good quality on our machine(SUS-304 stainless steel, more than 4mm thickness).

3. High quality on final product, low humidity content(Less than 1%) and impurities ( Less than 50PPM).

Plastic Bottle Washing Equipment Video:

Plastic Bottle Washing Equipment Detail:

Plastic Bottle Washing Equipment Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

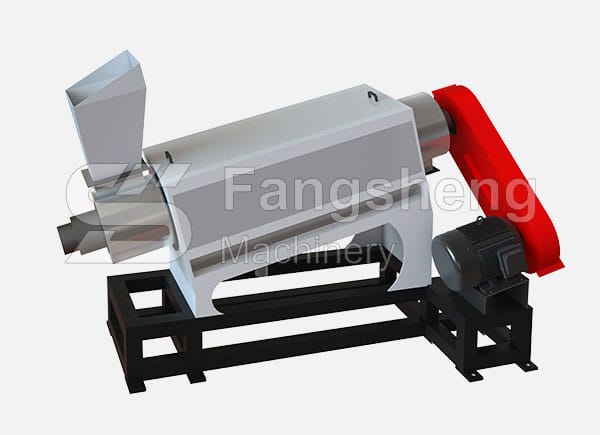

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

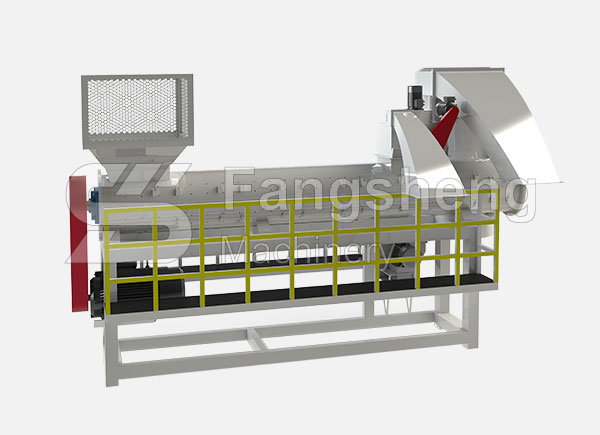

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |