Plastic Bottle Recycling Line Instruction:

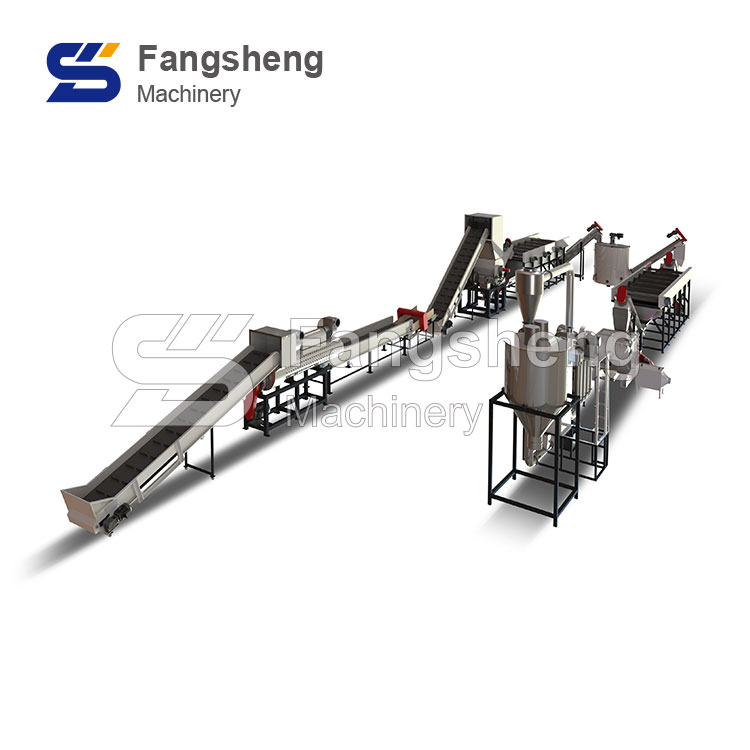

Plastic bottle recycling line is widely used to process PET bottles (coke bottles) and waste PET plastic crushed into flakes. Plastic bottle line is a crushing, cleaning and drying production line. PET flakes are mainly used for fiber production and other related PET products. The production line is highly automated, saves labor cost and has low post maintenance cost. Plastic bottle line adopts the international advanced industry concept and technology to meet the domestic and international waste plastic recycling. This PET recycling machine can be displayed in “L” or “U” shape according to the customer’s workshop.

This plastic bottle recycling machine is specially designed for recycling various water bottles, beverage bottles, juice bottles; such as cola bottles, pure water bottles. After the process of separation, label removal, wet crushing, friction and hot water cleaning, the products can be produced as polyester staple fiber, PET flakes, PET film, PET packing tape, etc.Plastic bottle recycling production line mainly includes plastic bottle label remover, plastic crusher, high temperature washing drum, scrubbing machine, dewatering machine, etc. This plastic recycling production line is mainly used for processing waste mineral water bottles, cola bottles and plastic bottles made of PET.

Plastic Bottle Line Advantages:

The excellent barrier property of PET material makes plastic bottle widely used in the packaging of carbonated drinks, fruit juices, milk and tea drinks. However, when these materials are discarded, we are faced with the problem of how to dispose of waste plastic bottles. The emergence of waste plastic bottle recycling plant can not only solve the problem of environmental pollution, but also provide a wide scope of investment profit. Recycling one ton of used plastic bottles is equivalent to saving 50,000 tons of oil and reducing 37,500 tons of carbon dioxide emissions.

Plastic bottle recycling machine refers to cleaning, crushing, granulating and molding of used plastic bottles. The whole plant involves these basic equipments: plastic bottle crusher, washing machine, screw feeder, debarer, dryer, and pellet mill. This system is one of the waste plastic recycling systems sold at Beston.

Plastic Bottle Line Video:

Plastic Bottle Line Detail:

Plastic Bottle Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |