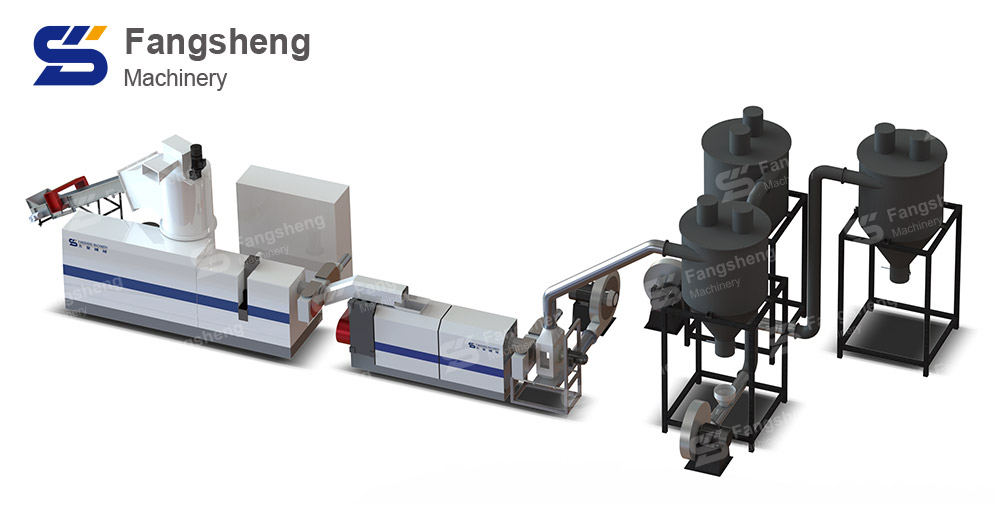

PLA Degradable Film Granulation Machine Description:

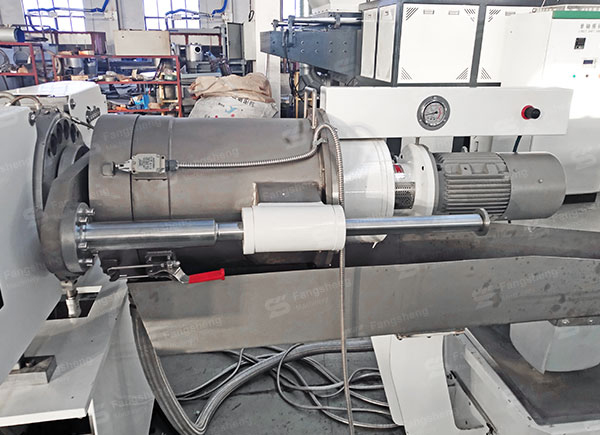

The PLA degradable film granulation machine is novel in design, reasonable in structure, stable in operation, low in noise, low in energy consumption, and high in output. The PLA degradable film granulation line is an ideal equipment for film pelletizing, especially for the recycling of crushed materials such as PLA and PBAT. The PLA degradable film granulator adopts a special screw design. The screw and barrel are specially hardened, which has the characteristics of abrasion resistance, good mixing performance and high output. It can drain away moisture and exhaust gas during the production process to make the discharge more stable. The rubber particles are stronger, which guarantees the excellent quality of the products.

PLA Degradable Film Granulation Machine Features:

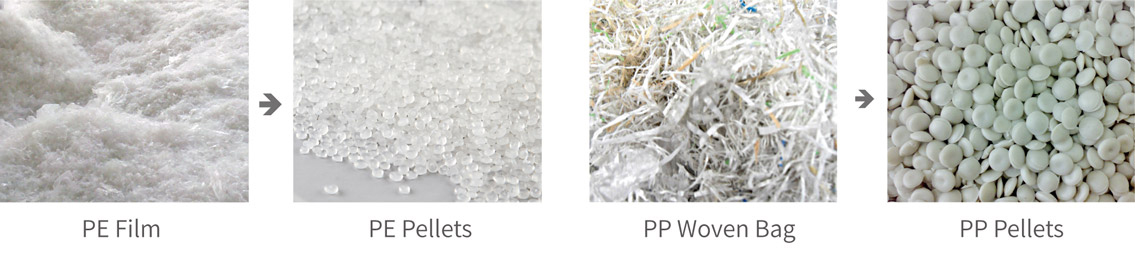

1. Fangsheng Machinery aims to provide the most advanced technology to recycle biodegradable waste plastic bags. Especially suitable for used biodegradable bags or trimmed bags.

2. With our new PLA Degradable film granulation equipment, it is easy to operate and labor-saving, and can be used for plastic recycling.

3. Our biodegradable PBAT PLA film granulation equipment is specially designed for processing residues and used biodegradable materials.

4. Considering the temperature of the biodegradable bag, we set the temperature of each part of the extruder to 140-175 degrees. The speed of the extruder is controlled at 100-150RPM. All designs are considered to be the properties of biodegradable plastics.

5. There are more and more biodegradable plastic films and bags, and they are becoming more and more popular.

PLA Degradable Film Granulation Machine Application:

PLA Degradable Film Granulation Machine Video:

PLA Degradable Film Granulation Equipment Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |

PLA Degradable Film Granulation Equipment Detail: