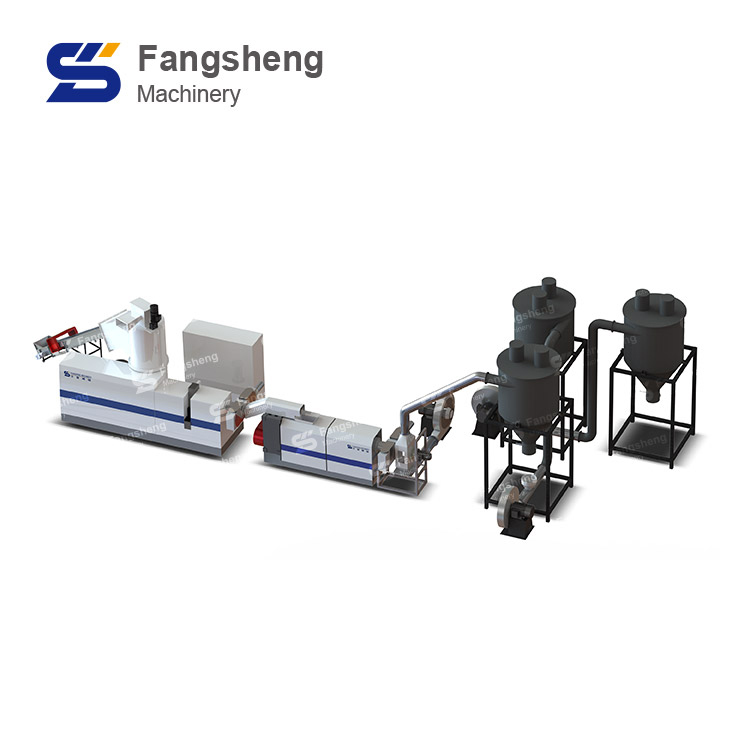

PLA Degradable Film Granulating Line Description:

The PLA degradable film granulating line adopts a three-machine integrated (crushing-washing-granulation) structure design. Through automatic operation, the production efficiency is high and the processing capacity is strong. The pelletizing unit completes one-time operation from feeding, crushing, cleaning, pelletizing, and pelletizing. The main and auxiliary machines and supporting equipment can be selected in a variety of specifications and models. Users can choose cost-effective options according to their own needs and budget. High configuration, and the entire PLA degradable film granulating machine can be customized design and production according to the area and space of the user’s production area, which can make more reasonable use of the delivery room space without waste.

PLA Degradable Film Granulating Line Features:

1. Our PLA degradable film granulating machine is specially designed for processing residues and used biodegradable materials.

2. Now, more and more biodegradable plastic films and bags are becoming more and more popular.

4. With the help of our film granulator, the operation is simple and labor-saving, and plastic recycling can be carried out.

5. Considering the temperature of the biodegradable bag, we set the temperature of each part of the extruder to 140-175 degrees. The speed of the extruder is controlled at 100-150RPM. All designs are considered to be the properties of biodegradable plastics.

PLA Degradable Film Granulating Line Application:

PLA Degradable Film Granulating Machine Video:

PLA Degradable Film Granulating Machine Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |