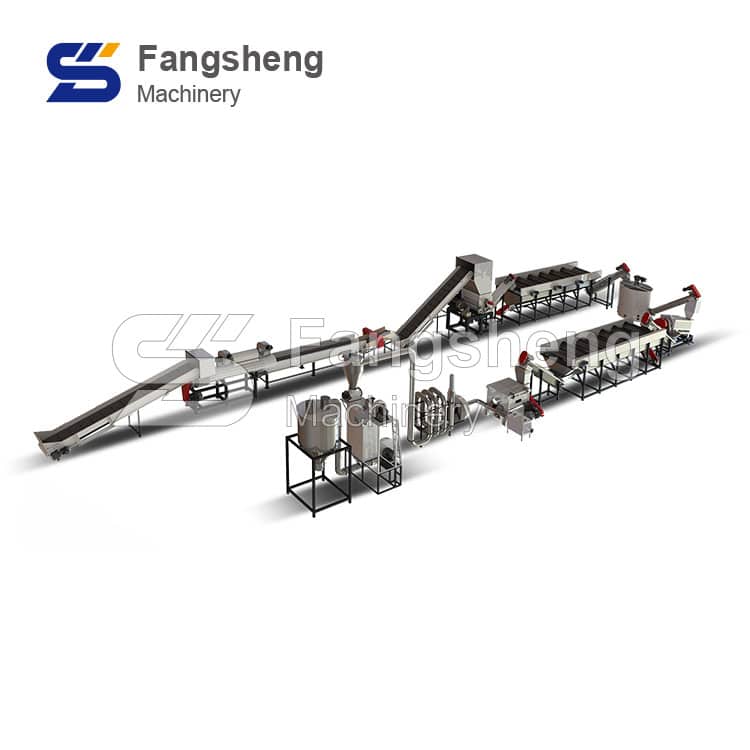

PET Bottle Recycling Machine Description:

PET bottle recycling machine is applied in waste PET bottles, water bottles, cola bottles etc. Through crushing, washing and dry process, the waste bottle will become to be bottle flakes. The flakes are widely used in plastic industry, like sheet, and profile production. The clean flakes can be used to produce the polyester staple fiber, PET strap band, granules, PET transparent film and sheets, etc.

PET bottle recycling line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products are very clean. PET bottle recycling line output we can supply is from 300kg/h to 2000kg/h.

PET bottle recycling line including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular. Which can remove ferrous and nonferrous metals, sand, oil, glue, paper and many other different contaminants efficiency.

PET Bottle Recycling Machine Application:

PET Bottle Recycling Line Video:

PET Bottle Recycling Line Detail:

PET Bottle Recycling Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |