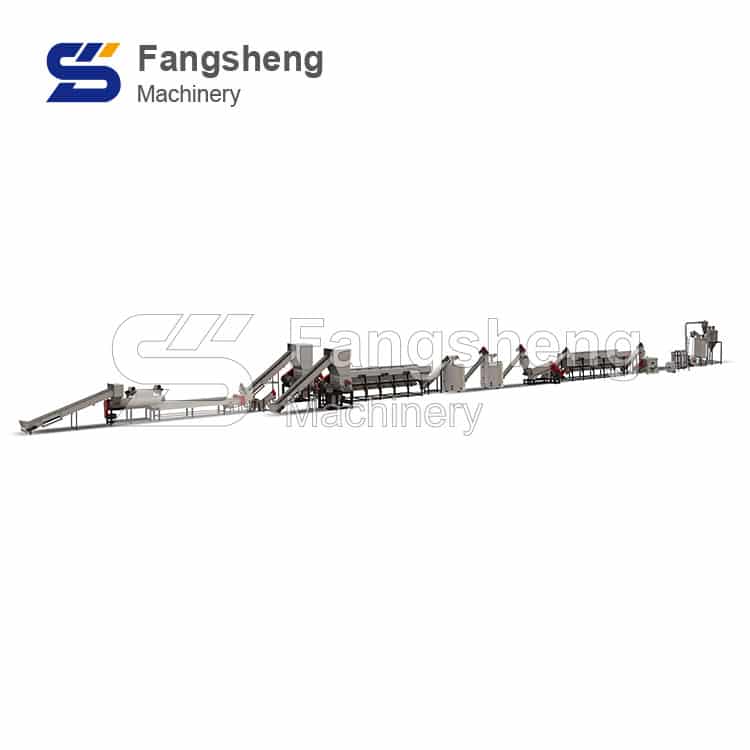

PET Bottle Recycling Line Instruction:

PET bottle recycling line is suit for PP/PE/PET Flakes, from crushing ,washing and drying in 300-500kgs/h , you can select the equip as your requirement , there have cold wash and hot wash for your choose, PET recycling line is a economic and more used to make good good quality pellets after wash .Each machine will be designed be perfect.

1.Description

1. PET recycling line washing and drying line is suitable for high capacity.

2. PET recycling line washing is a whole line consists bottle label peeler, crusher,washing machine and dewatering machine.

3. PET recycling line washing is an automatic production line which produces high quality production.

2.Characteristic

1.Automatically works,conveying material,peeling label,crushing,washing,drying.

2.Hot washing for PET flakes by using steam.

3.Moisture for the end production.

4.Impurity pvc is less than 1% in production.

PET Recycling Line Video:

PET Bottle Recycling Line Detail:

PET Recycling Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |