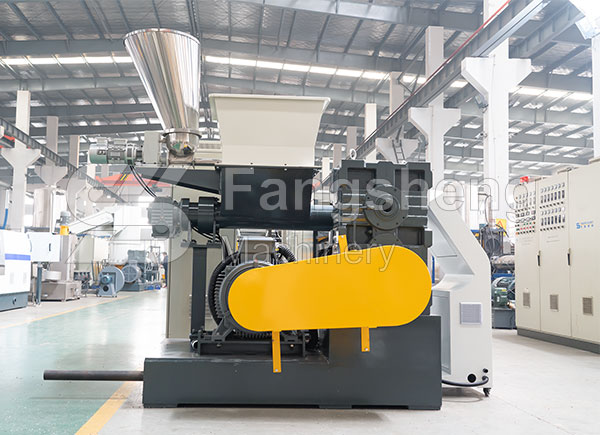

PE PP Film Pelletizing Line Description:

PE PP film pelletizing line adopts the principle of squeezing dehydration, equipped with imported hydraulic equipment, and equipped with PLC touch screen control. The film pelletizing line is used for soft plastics such as plastic film and plastic bags. The film pelletizing line makes full use of the high-pressure friction non-stop heating system to automatically heat the production, avoiding continuous heating, saving electricity and energy. The film pelletizing machine adopts a split automatic power distribution system to ensure the safe and normal operation of the motor.

PE PP Film Pelletizing Line Features:

1. The film pelletizing line adopts a forced feeding device, and the host and pelletizer can be controlled by a frequency converter or programmable remotely.

2. The screw and barrel are made of 38CrMoAl, and the surface is nitrided and hardened, so the service life is super long.

3. The film pelletizing machine is directly cut by water ring above the die, either horizontal or vertical water ring. After cooling, the water enters the centrifugal dewatering machine, and then is sent to the storage bin by the fan without the problem of wire breakage.

PE PP Film Pelletizing Machine Application:

PE PP Film Pelletizing Machine Video:

PE PP Film Pelletizing Machine Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |

PE PP Film Pelletizing Machine Detail: