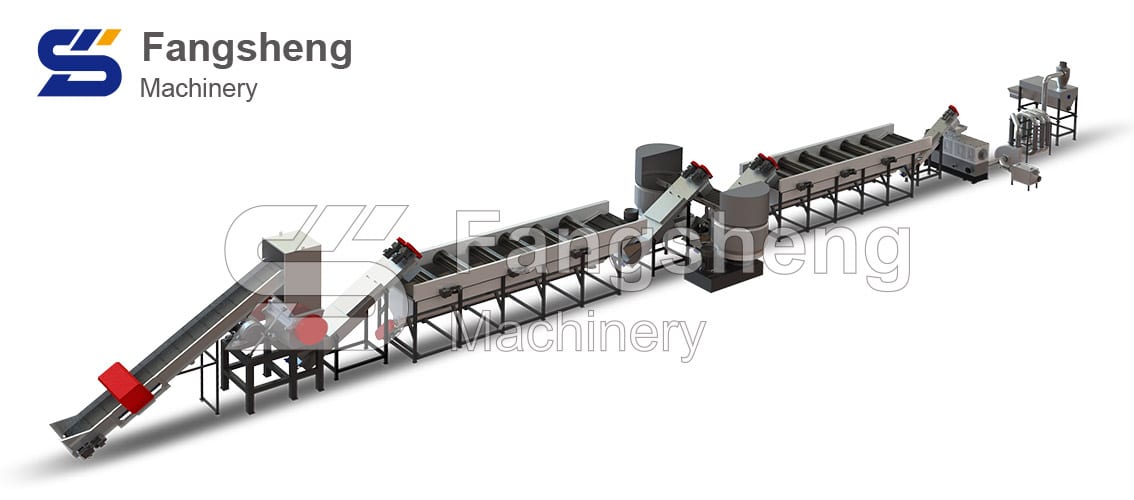

PE Film Recycling Washing System Description:

The PE film recycling washing system plants convert dirty bottles into clean PET flakes. These flakes can be further processed and reused with high commercial value. Our PET bottle cleaning and recycling line can have a capacity of 300kg/h to 3000kg/h. The main purpose of this line is to obtain clean flakes from dirty mixed bottles or flakes during the processing of the entire cleaning line. The PE film recycling washing line also obtains clean PP/PE collection, labels and paper flakes etc.

The equipment is divided into process steps such as opening, washing, sorting, metal detection, crushing, float washing, hot washing, scrubbing, rinsing, dewatering, drying and packaging.

PE Film Recycling Washing System Machine Features:

1、The PE film recycling washing line has high efficiency and low energy consumption; high automation and low manpower consumption.

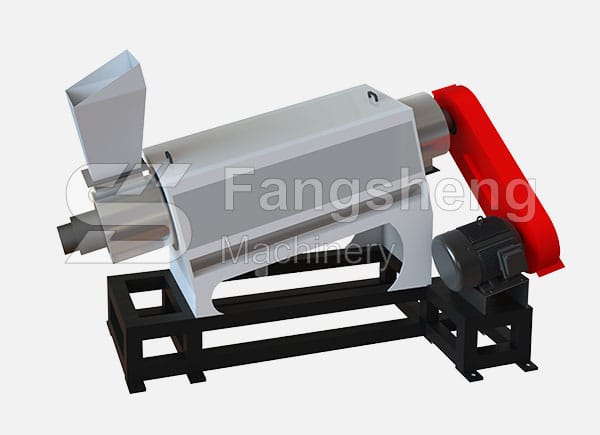

2、The heavy-duty crusher adopts 10 rotating blades for efficient cutting, and adopts water spraying device for material pre-washing and machine cooling.

3、Through multiple friction cleaning and rinsing, the film washing line can fully clean oil, mud and other dirty materials.

4、Reasonable flow chart design, easy to operate and reduce maintenance cost.

5、Total solution of sewage recovery.

6、Rinsing tank, spiral feeder, pipeline and bin are made of SUS304 stainless steel.

7、The machine has solid structure, good balance performance, stable operation and long service life.

8、High quality motor and electrical components ensure safety.

Film Cleaning Equipment Application:

Film Cleaning Equipment Video:

Film Cleaning Equipment Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 4500*690 | – | – | According to customers standard |

| Wet crusher | 75 | – | 2-4 | – | |

| Friction washer | 2.2*2 | 3000*300 | 1-2 | 3-5 | |

| Floating washer | 2.2*2+1.5 | 4500*1300 | 2-4 | 3-5 | |

| Screw conveyor | 2.2 | 2500*250 | 1-2 | 3-5 | |

| High-speed friction washer | 30 | – | 2-4 | 3-5 | |

| Screw converor | 2.2 | 2800*300 | 1-2 | 3-5 | |

| Dewatering machine | 75 | – | – | 5 | |

| Drying system | 36 | – | – | – | |

| Storage hopper for transition | – | – | – | – | |

| Drying system | 36 | – | – | – | |

| Storage hopper | 2.2*2 | – | – | – |

Film Cleaning Equipment Detail: