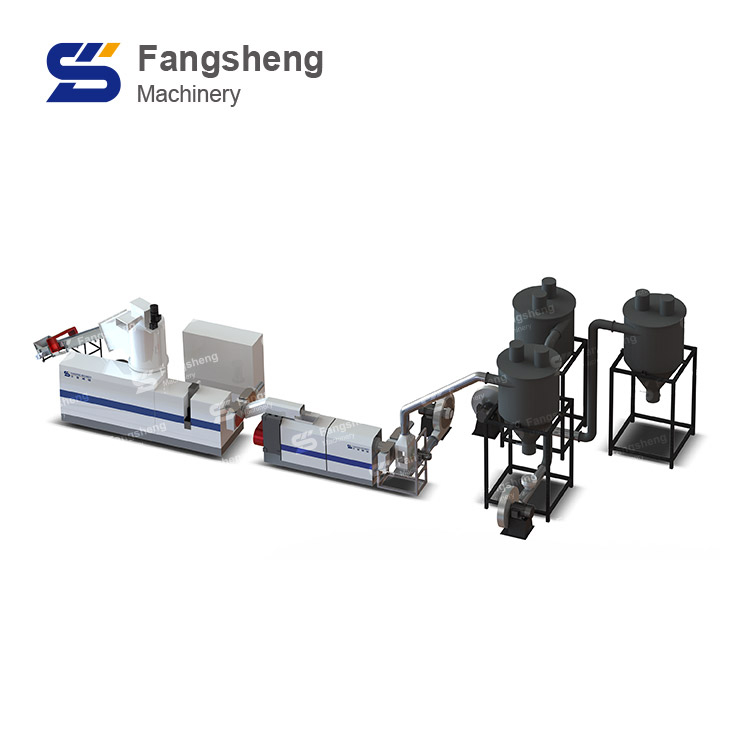

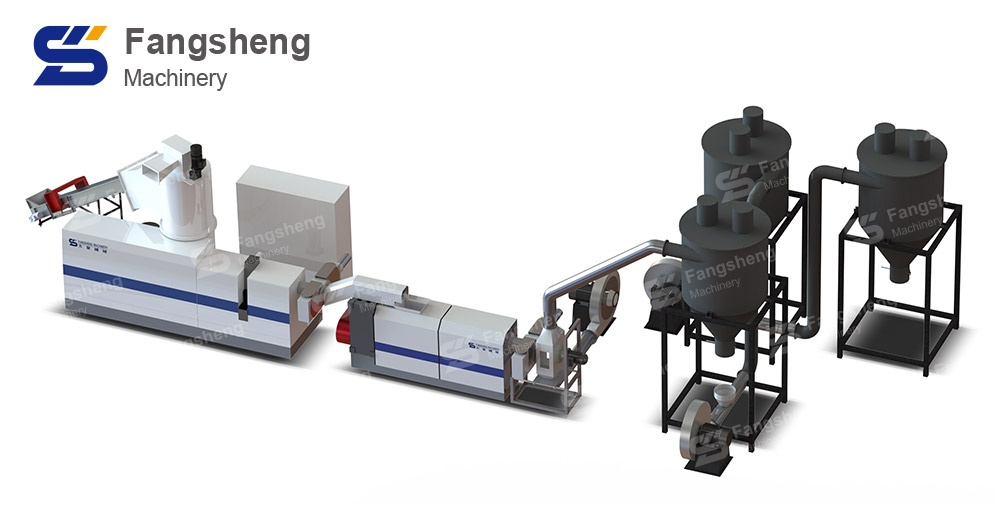

PBAT Degradable Film Granulation Machine Description:

The PBAT degradable film granulation machine is equipped with a forced feeder, fast mesh changer and automatic rhermocontroller.This raw materials like waste films of PBAT and PLA are extruded through the extruder, and then are cooled through wind and cut hotly into granules, featuring in fine quality, bubble free and moisture free. The granulator is easy to change the screen, adopts the exhaust design, and has the characteristics of high productivity and low energy consumption.

PBAT Degradable Film Granulation Machine Features:

1. Specially designed professional plasticizing screw for degradable materials, combined with advanced production technology, can effectively avoid fish eyes on the film.

2. The PBAT degradable film granulation system adopts touch screen, PLC control system and specially designed safety switch, which makes the operation more convenient and safer.

3. The product produced by our PBAT degradable film granulation line is a high-end biodegradable material with low carbon and environmental protection characteristics.

PBAT Degradable Film Granulation Machine Application:

PBAT Degradable Film Granulation System Video:

PBAT Degradable Film Granulation System Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |