Paint bucket recycling washing line is special for paint bucket, chemical barrel crushing, washing and drying production line.

Paint bucket recycling washing line is developed by Fangsheng Machinery introducing, digesting and absorbing domestic and foreign advanced ideas and technology, and combining with the development of the demand and the characteristics of waste plastics recycling. Paint bucket recycling washing machine can meet the domestic and international environmental protection requirements for waste plastics recycling.

Paint Bucket Recycling Washing Line Advantages:

1.Manufacture procedures start from crushing, washing to final separating, Fangsheng Machinery will design according to customer’s requests recycling washing line.

2.Fangsheng Machinery will re-offer professional design process diagram and detailed recycling washing line information for customer once order is confirmed.

3.Waste bucket recycling washing line using electrical control security design to ensure the safety of operators.

Paint Bucket Recycling Washing Line Video:

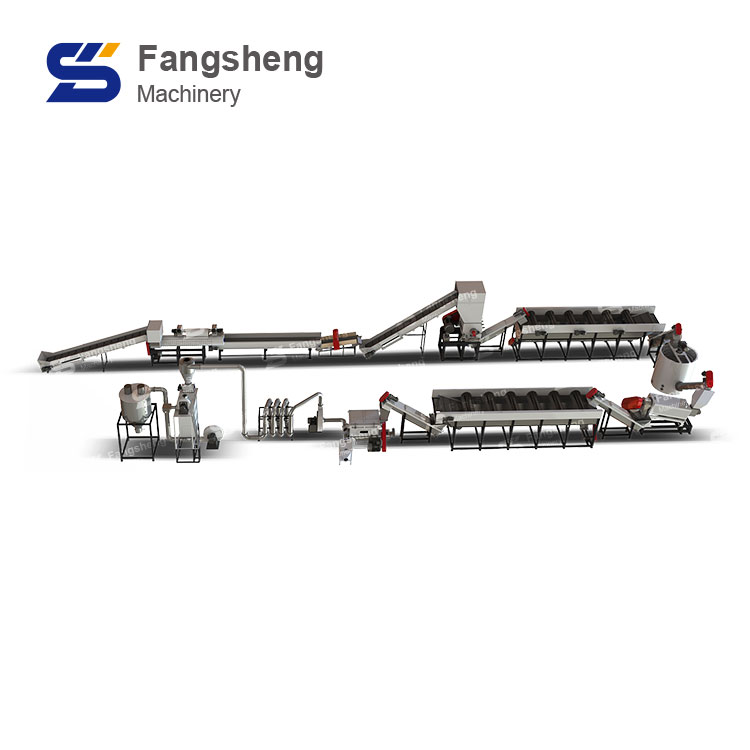

Paint Bucket Washing Line Flow Chart:

Belt conveyer → Wet crusher → Screw conveyer → Floating washer → Screw conveyer → High speed friction washer → Screw conveyer → Dewatering machine → Drying system1 → Silo for transition → Drying system2 → Storage hopper

Paint Bucket Washing Line Application:

Paint Bucket Washing Line Detail:

Paint Bucket Washing Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |