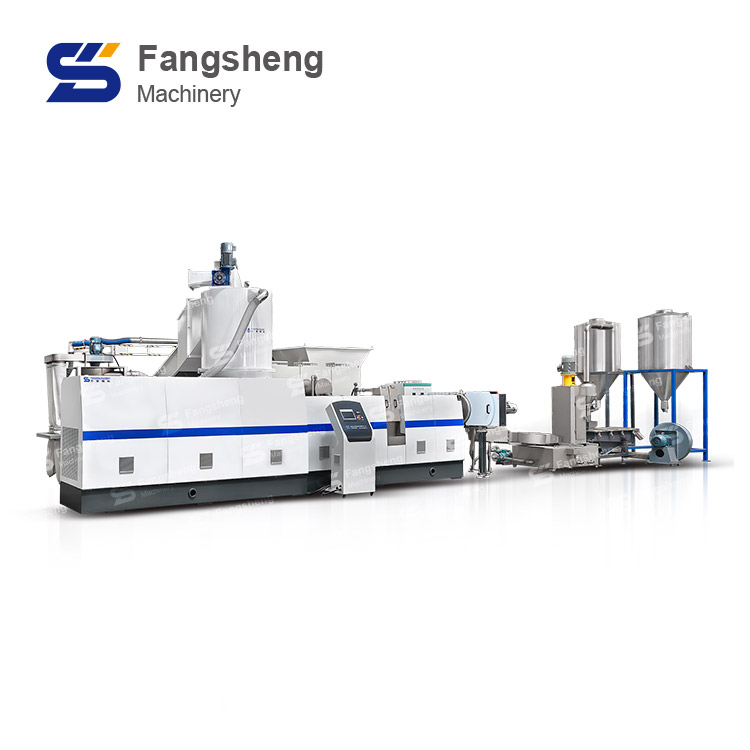

HDPE LDPE PE PP film compactor pelletizing machine is designed with latest technology, the compactor pelletizing machine is a very integrated system which can be used for a wide range of materials. The extruder is combined together with agglomerator and feeding belt, the raw material will be compacted firstly in the agglomerator,then get into screw immediately, in this way, the material feeding is much more stable and the output is bigger, especially for HDPE LDPE PE PP film, PP bags and other soft material.The agglomerator equipped with cutting blades can process massive material like shopping bags, woven bags, and film in roll, no need to crush the materials in advance.With frequency control, this film compactor pelletizing line also can process rigid regrind materials.

Film Compactor Pelletizing Machine Advantage:

1. Save manpower and the whole film pelletizing production line only need 1~2 workers to operate.

2. No need another crusher to crushing material into pieces, big material can be feed to machine directly. Save time and very convenient.

3. The film pelletizing line has low energy consumption, as well save the cost.

4. The granules will high quality and beautiful.

Film Compactor Pelletizing Machine Video:

Film Compactor Pelletizing Line Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |