HDPE Film Pelletizing Line Description:

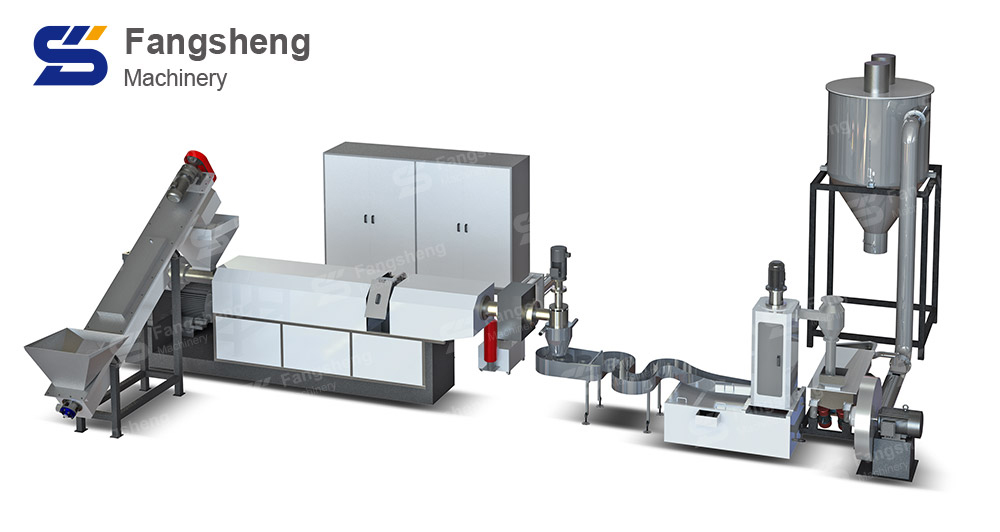

Fangsheng’s high-efficiency HDPE film pelletizing line is designed for post-processing of printed and non-printed PE polyethylene (HDPE, LDPE, LLDPE) and PP polypropylene flexible packaging materials.The HDPE film pelletizing machine integrates a compactor system to eliminate the need for pre-cutting materials, requires less space and energy consumption, and at the same time can produce high-quality plastic granules with high productivity.

HDPE Film Pelletizing Line Features:

1. The film can be cut and compressed in a compactor, and then fed into a single screw extruder. Our design ensures that the HDPE film pelletizing machine has a long service life and is economical to use.

2. Low cost after redesign: Now this kind of HDPE film pelletizing machine is more economical on both power supply and water. In the long service life of this granulator, it can save a lot of energy!

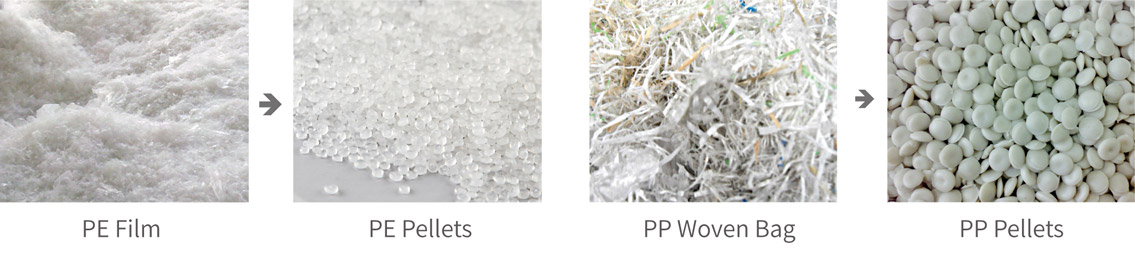

3. The HDPE film production line is suitable for recycling and pelletizing various plastic waste films such as PP, HDPE, LDPE, LDPE film and clean woven/non-woven bag materials.

4. You can choose to use a single-stage or two-stage plastic film granulator according to the cleanliness of the material; you can choose a cooling cutting system or a die surface thermal cutting system.

HDPE Film Pelletizing Line Application:

HDPE Film Pelletizing Machine Video:

HDPE Film Pelletizing Machine Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |

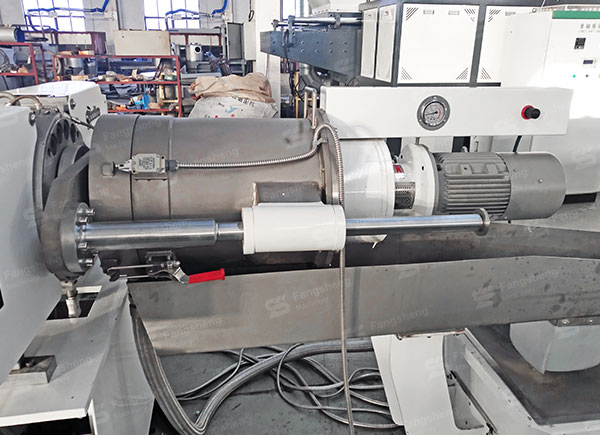

HDPE Film Pelletizing Machine Detail: