Garbage Film Washing Machine Instruction:

Garbage film washing machine is widely used to clean and recycle waste PP/PE plastic soft plastics. Such as shopping bags, packaging film, garbage bags, woven bags, non-woven bags and films. This recycling machine can crush and clean the dirty soft plastics and dry them into clean film sheets. After the plastic film/bag pieces are cleaned, they can be made into granules/granules with the next process, which is called plastic granulator.

The garbage film washing line is highly automated, low consumption, can save labor, save electricity and water, and easy to maintain.

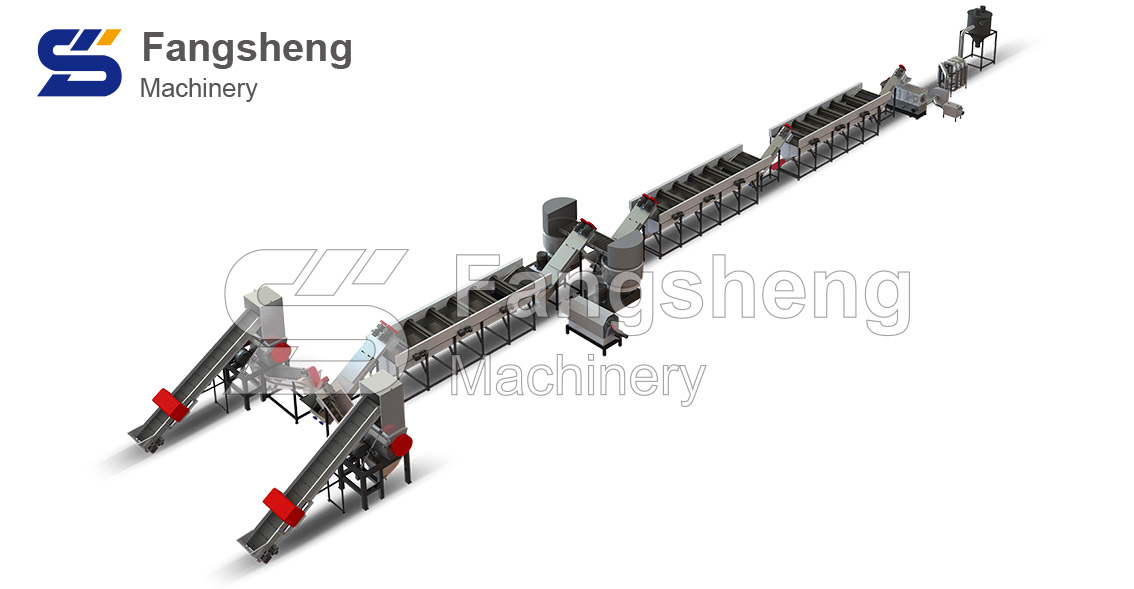

With advanced design, concept and technology, the washing line is suitable for different states of waste plastic bags/films. This PE PP plastic waste film fiber washing machine plant can be “L”, “S” or “U” shaped according to different workshop layouts.

The PE agricultural film PE garbage film washing and recycling machines is a complete line for crushing washing and drying of PE agricultural film, PE garbage film and other soft waste plastic materials like LLDPE stretch packing film, HDPE shopping bags, LDPE garbage bags, PP woven bags and PP jumbo bags,etc.

Garbage Washing Machine Application:

Garbage Washing Machine Video:

Garbage Washing Machine Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 4500*690 | – | – | According to customers standard |

| Wet crusher | 75 | – | 2-4 | – | |

| Friction washer | 2.2*2 | 3000*300 | 1-2 | 3-5 | |

| Floating washer | 2.2*2+1.5 | 4500*1300 | 2-4 | 3-5 | |

| Screw conveyor | 2.2 | 2500*250 | 1-2 | 3-5 | |

| High-speed friction washer | 30 | – | 2-4 | 3-5 | |

| Screw converor | 2.2 | 2800*300 | 1-2 | 3-5 | |

| Dewatering machine | 75 | – | – | 5 | |

| Drying system | 36 | – | – | – | |

| Storage hopper for transition | – | – | – | – | |

| Drying system | 36 | – | – | – | |

| Storage hopper | 2.2*2 | – | – | – |