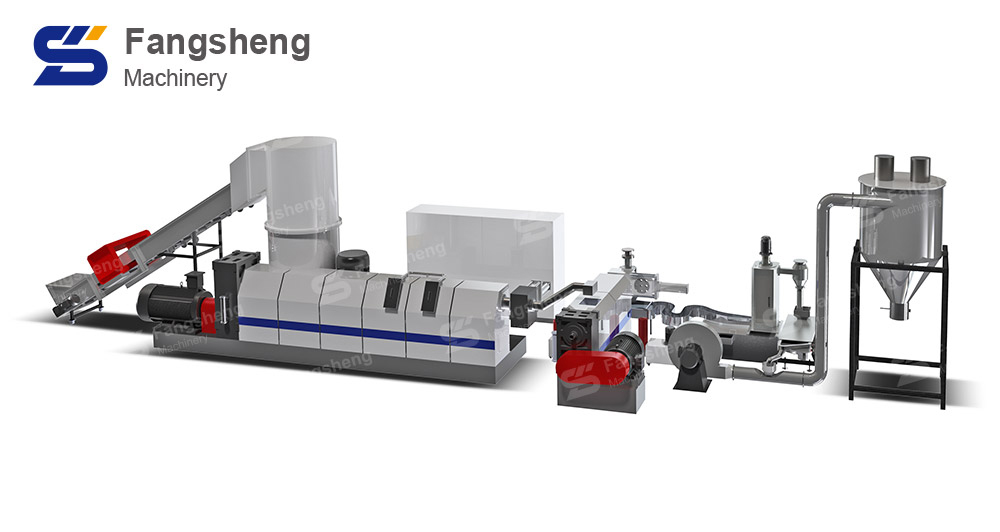

CPP Film Granulation Line Description:

This CPP film granulation line is widely used to process waste plastic mixed materials into clean film sheets, including plastic film, PP waste woven bags, plastic bags, plastic garbage, and waste plastic covering film. After the film is cleaned, the next step of granulation can be carried out, which is called a granulation production line. The CPP film granulation machine has a high degree of automation, saves labor costs, and has a low cost after maintenance. Relying on advanced international industry concepts and technologies, can meet the recycling and utilization of waste plastics at home and abroad.

CPP Film Granulation Machine Features:

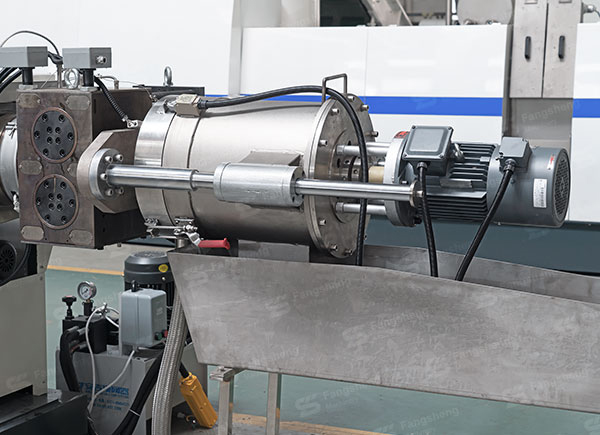

1. In order to be able to plasticize and shape plastics, the CPP film granulation machine changes the physical properties of plastics through the process of high-temperature melting, plasticization and extrusion.

2. We have added a certain power heating ring outside the specific head of the CPP film granulator to ensure the normal and full discharge of the material. It solves the problem of plastics hindering extrusion due to lower temperature and insufficient fluidity during the extrusion process.

3. Through the evenly distributed heating ring outside the barrel, the temperature can be automatically adjusted by the instrument on the electric cabinet, and the heating and plasticizing of the material in the barrel can be completed evenly.

4. Forced feeder: The forced feeder adopts thrust bearing instead of traditional roller bearing, which is more efficient

CPP Film Granulation Machine Application:

CPP Film Granulation Machine Video:

Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |

CPP Film Granulation Machine Detail: