Chewing gum bottle recycling washing line after selection, wet crushing, friction washing and etc procedures, the dust, oil on the film can be completely cleaned. The recycled products are being widely used in granulation, injection and other fields.

Chewing Gum Bottle Recycling Washing Line Advantages:

1.Final products has good quality. When process chewing gum bottle, final products humidity below 1%, impurities100ppm,PVC label content 100ppm . The whole line capacity between 300kg/h-2000kg/hour.

2.Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service lift time.

3.World famous brand components applied on the chewing gum bottle washing line – e.g. SKF bearing, Siemens contactor, Omron temperature, FUJI invertor, Siemens PLC controller, etc.

4.The chewing gum bottle washing line with CE certification, ISO9001 certification.

Chewing Gum Bottle Recycling Washing Line Video:

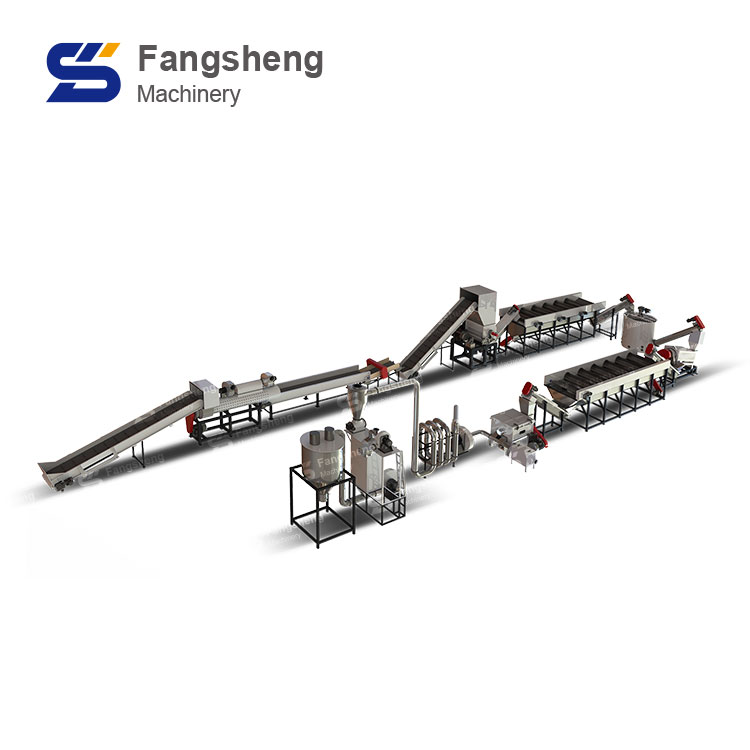

Chewing Gum Bottle Washing Line Flow Chart:

Belt conveyer → Wet crusher → Screw conveyer → Floating washer → Screw conveyer → High speed friction washer → Screw conveyer → Dewatering machine → Drying system1 → Silo for transition → Drying system2 → Storage hopper

Chewing Gum Bottle Washing Line Application:

Chewing Gum Bottle Washing Line Detail:

Chewing Gum Bottle Washing Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |