The chemical barrel recycling washing line is used for washing and recycling of PE, PP, PVC barrels. Coordinating the washing recycling line with follow programmed work (granulating machine), and will make waste and dirty PE, PP, PVC barrels to be the PE, PP, PVC granule material and in order to producing new PE, PP, PVC materials.

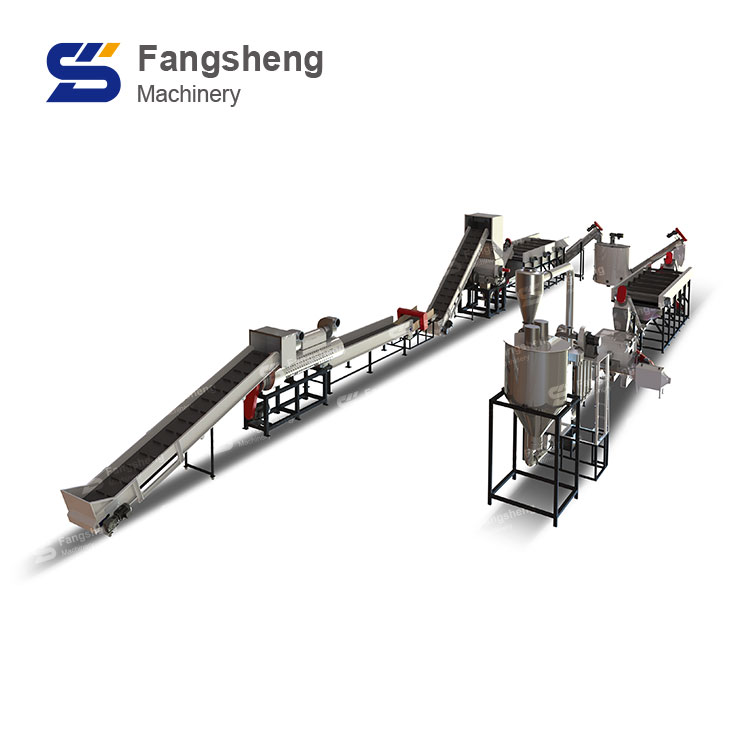

This waste barrel recycling washing line consists of: conveyor, crusher (grinder), washing machine, put the feeder, squeezed dehydration machine, control cabinet and other components.

First of waste barrel sorting (classification), broken (torn), then friction wash, rinse, and finally squeezed drawing granulation machine dehydration after drying, granulation.

The waste barrel washing production line from scrap to finished product, and efficient cleaning of waste plastics. Simple operation, high efficiency, environmental protection, energy saving.

Chemical Barrel Recycling Washing Line Video:

Chemical Barrel Recycling Washing Line Flow Chart:

Belt conveyer → Wet crusher → Screw conveyer → Floating washer → Screw conveyer → High speed friction washer → Screw conveyer → Dewatering machine → Drying system1 → Silo for transition → Drying system2 → Storage hopper

Chemical Barrel Washing Line Application:

Chemical Barrel Washing Line Detail:

Chemical Barrel Washing Line Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |