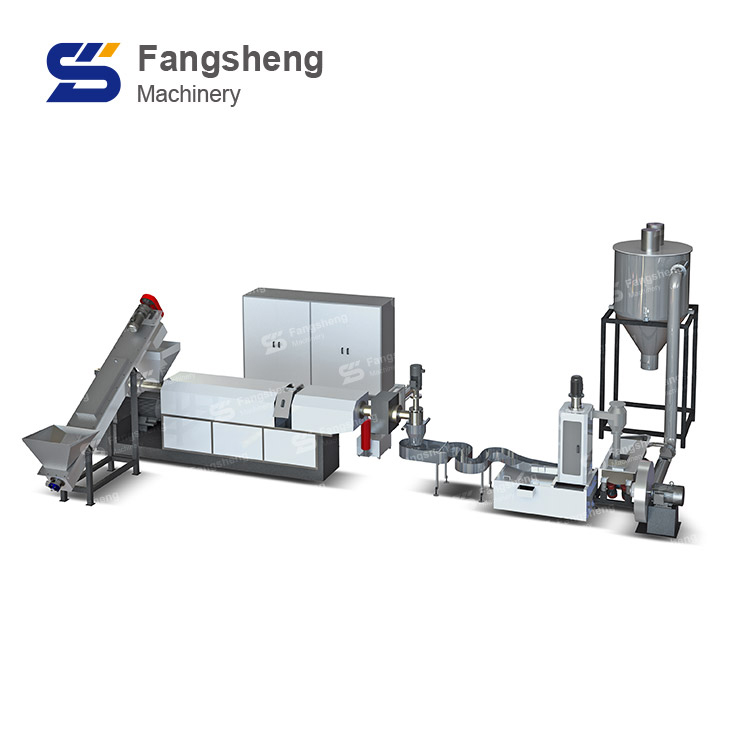

BOPP Film Pelletizing Line Description:

The BOPP film pelletizing line can drain away moisture and exhaust gas during the production process, so that while the discharge is stable, the rubber particles produced are stronger. It is derived from the special screw design of the granulator after hardening treatment and the high-torque gearbox design. The BOPP film pelletizing machine is smooth and noiseless during operation. Such a granulator has good mixing performance, high output, and at the same time guarantees the excellent quality of the product.

BOPP Film Pelletizing Line Features:

1) Single stage extruder and double stage extruders can be used according to user’s requirement or material condition.

2) Plastic pelletized PP,BOPP, HDPE, ABS and other engineering plastics or general plastics recycling and granulation.

3) Granules cutting type: water ring face cutting, strip/noodle type cutting and hot cutting;

4) Waste woven bags and waste film can be directly put into the granulation line without crushing.

5) The main engine is equipped with full automatic control cabinet and PLC operating system.The BOPP film pelletizing machine is easy to operate and has stable performance.

6) Low energy consumption, remarkable energy saving effect, high output, mechatronics.

BOPP Film Pelletizing Line Application:

BOPP Film Pelletizing Line Video:

BOPP Film Pelletizing Machine Technical Parameter:

| FS series single-stage granulator machine | ||||||

|---|---|---|---|---|---|---|

| Model | Extruder | Screw diameter(mm) | L/D ratio | Power(kw) | Productivity(PE)(kg/h) | Productivity(PP)(kg/h) |

| FSJ70 | 70/33 | φ70 | 33:1 | 110 | 110-150 | 100-130 |

| FSJ85 | 85/33 | φ85 | 33:1 | 150 | 180-250 | 150-200 |

| FSJ100 | 100/33 | φ100 | 33:1 | 210 | 280-350 | 250-300 |

| FSJ130 | 130/33 | φ130 | 33:1 | 300 | 480-550 | 400-480 |

| FSJ160 | 160/33 | φ160 | 33:1 | 370 | 650-750 | 550-650 |

| FSJ180 | 180/33 | φ180 | 33:1 | 460 | 800-1000 | 750-850 |

| FS series double-stage granulator machine | ||||

|---|---|---|---|---|

| Model | FSJ100/120 | FSJ130/130 | FSJ160/160 | FSJ180/200 |

| First extruder parameter | ||||

| Screw diameter(mm) | φ100 | φ130 | φ160 | φ180 |

| L/D ratio | 33 | 33 | 30 | 30 |

| Extruder motor(kw) | 90 | 132 | 185 | 250 |

| Heating power(kw) | 45 | 55 | 70 | 70 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Second extruder parameter | ||||

| Screw diameter(mm) | φ120 | φ130 | φ160 | φ200 |

| L/D ratio | 10-15 | 10-15 | 10-15 | 10-15 |

| Extruder motor(kw) | 30 | 45 | 55 | 75 |

| Heating power(kw) | 30 | 35 | 45 | 60 |

| Screw speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 |

| Productivity(kg/h) | 250-350 | 400-550 | 500-700 | 800-1000 |