Beverage Bottle Washing Line Features:

1. The whole beverage bottle washing line is designed with the suspension operation method of jamming the bottle neck, which makes the bottle stable and reliable under high speed operation, and at the same time greatly reduces the number of replacement parts, making the bottle washing machine more convenient and fast when changing the bottle type.

2. Adopting a new generation of stainless steel flip bottle clips, so that the bottle clips do not touch the upper part of the bottle threads, and with a spray nozzle, so that the inner wall of the bottle gets fully flushed without dead ends.

3. Adopting advanced pressure filling process, filling is fast, stable and accurate.

4. Advanced crown cap structure is adopted, without any damage to the surface of the bottle cap.

5. The whole machine adopts human-machine interface touch screen keypad, PLC computer control, and is equipped with missing cap and overload protection alarm device, which can detect and troubleshoot in time, and has high degree of production automation.

6. The parts in contact with water are made of high quality stainless steel, and the main electrical components are products of international famous manufacturers.

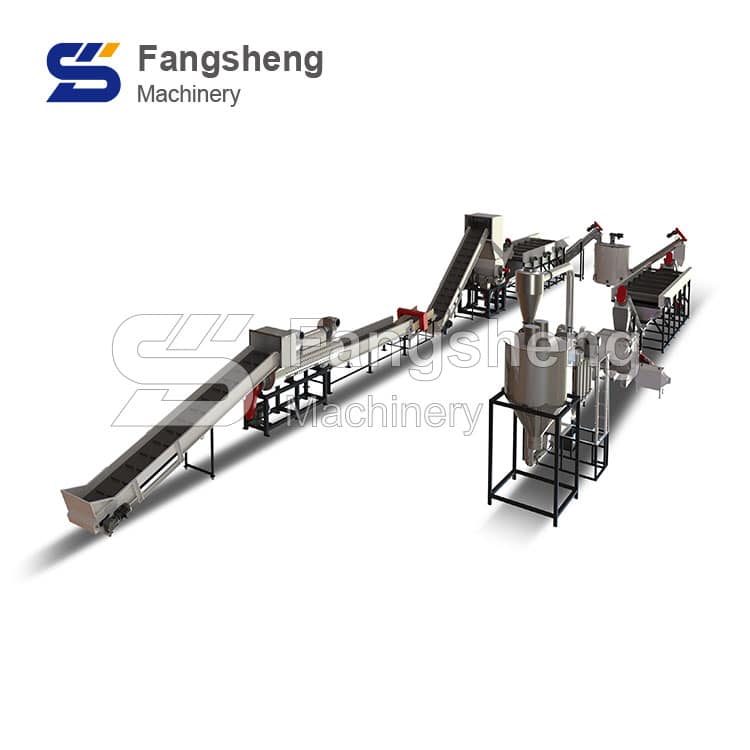

Bottle Washing Machine Description:

This bottle washing machine is to crush and wash waste plastic PET bottles for recycling. This PET plastic recycling machine is composed of label remover, sorting machine, crusher, cold washing machine, hot washing machine, dewatering, and packaging system. The bottle washing machine can get clean PET flakes from PE PP bottle caps, oil, PVC labels and then reuse PET flakes to avoid plastic contamination.

This PET plastic recycling machine can easily clean and recycle used PET bottles. Used and dirty PET bottles can be processed step by step in this PET plastic recycling machine. The bottle washing machine is specially designed for recycling PET bottles. We are equipped with a drying system at the end of the cleaning line, so that the completely dried flakes can be collected and packaged directly after cleaning.

Bottle Washing Machine Video:

Bottle Washing Machine Detail:

Bottle Washing Machine Technical Parameter:

| Name | Motor power (kw) | Dimension (mm) | Water consumption (T/H) | Stainless steel standard (mm) | Electric standard |

|---|---|---|---|---|---|

| Belt conveyor | 2.2 | 3500*900*3000 | – | – | According to customers standard |

| Label scraping machine | 11 | 2600*1200*1800 | 0.6-1.0 | 3-5 | |

| Manual separating machine | 2.2 | 6000*800*1200 | – | – | |

| Metal detectory | 0.4 | 2200*1200*1500 | – | 3-5 | |

| Belt conveyer | 2.2 | 3500*900*3000 | – | – | |

| Crusher | 37 | 2200*2200*3000 | 0.6-1.0 | – | |

| Screw converor | 3 | 2800*800*2600 | – | 3-5 | |

| High speed friction washer | 30 | 3200*1400*2000 | 1-2 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 36 | 2800*800*2600 | – | 3-5 | |

| Steam washer | 7.5 | 1800*1800*2700 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Floating washer | 3*2 | 5200*1700*2200 | 0.5-1.5 | 3-5 | |

| Screw conveyer | 3 | 2800*800*2600 | – | 3-5 | |

| Dewatering machine | 5.5 | 800*2200*2200 | – | 5 | |

| Drying system | 11 | 3500*2200*2200 | – | 3-5 | |

| Label separater | 4 | 800*1100*3800 | – | – | |

| Storage hopper | – | 1500*1500*3800 | – | – | |

| Electric elements | – | 2000*450*1780 | – | – |